Introduction

Biomass fuel is becoming an increasingly popular source of renewable energy because it is environmentally friendly and has a low carbon footprint. Biomass fuel feeding systems are used to transfer biomass fuels from the storage silos to the boilers for combustion. In this blog, we will be discussing the main components of a biomass fuel feeding system and how they work.

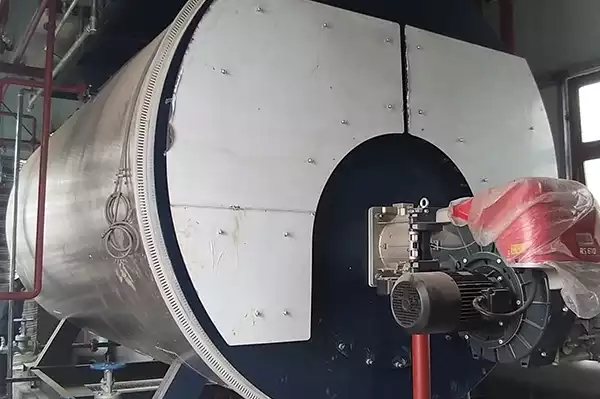

What is a biomass boiler system?

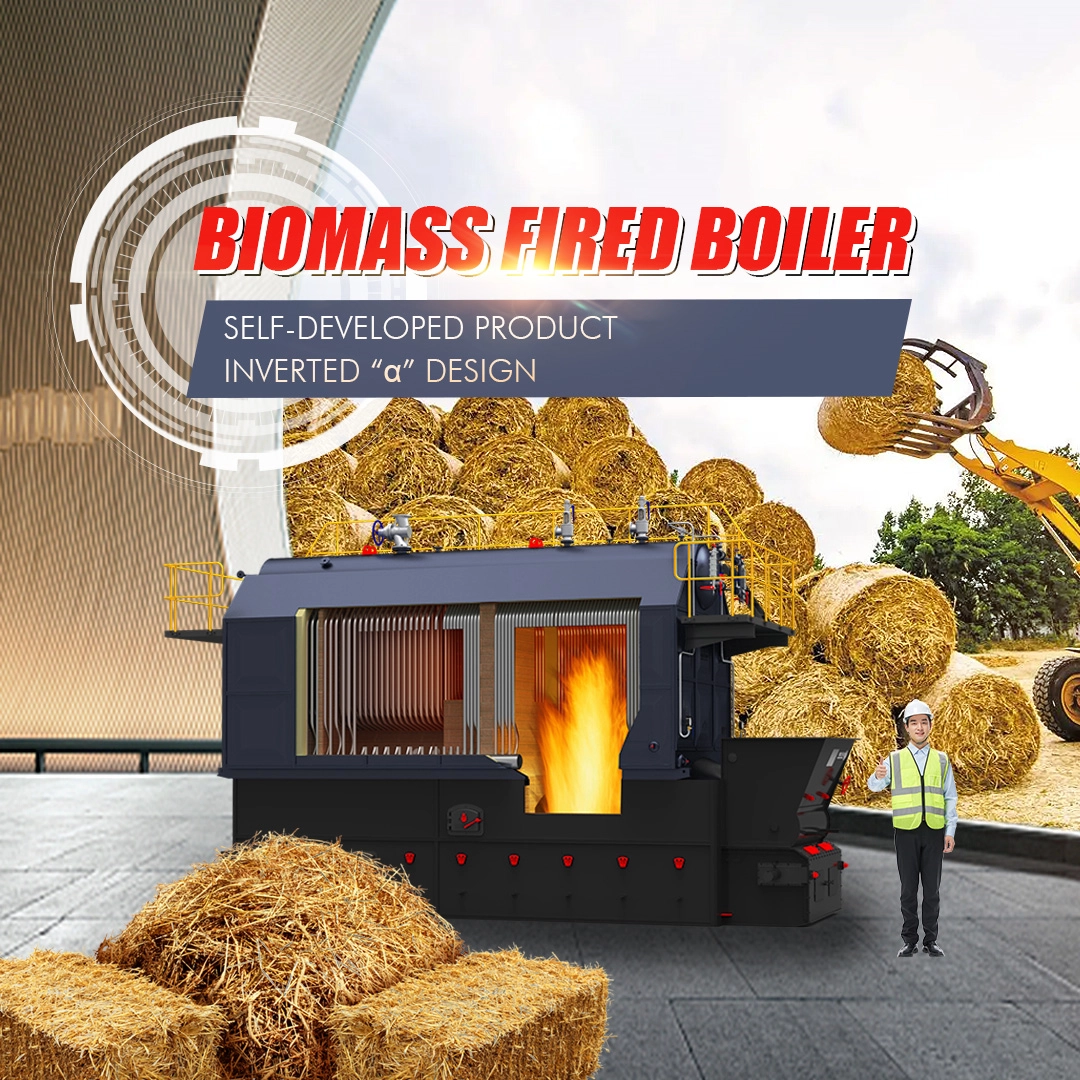

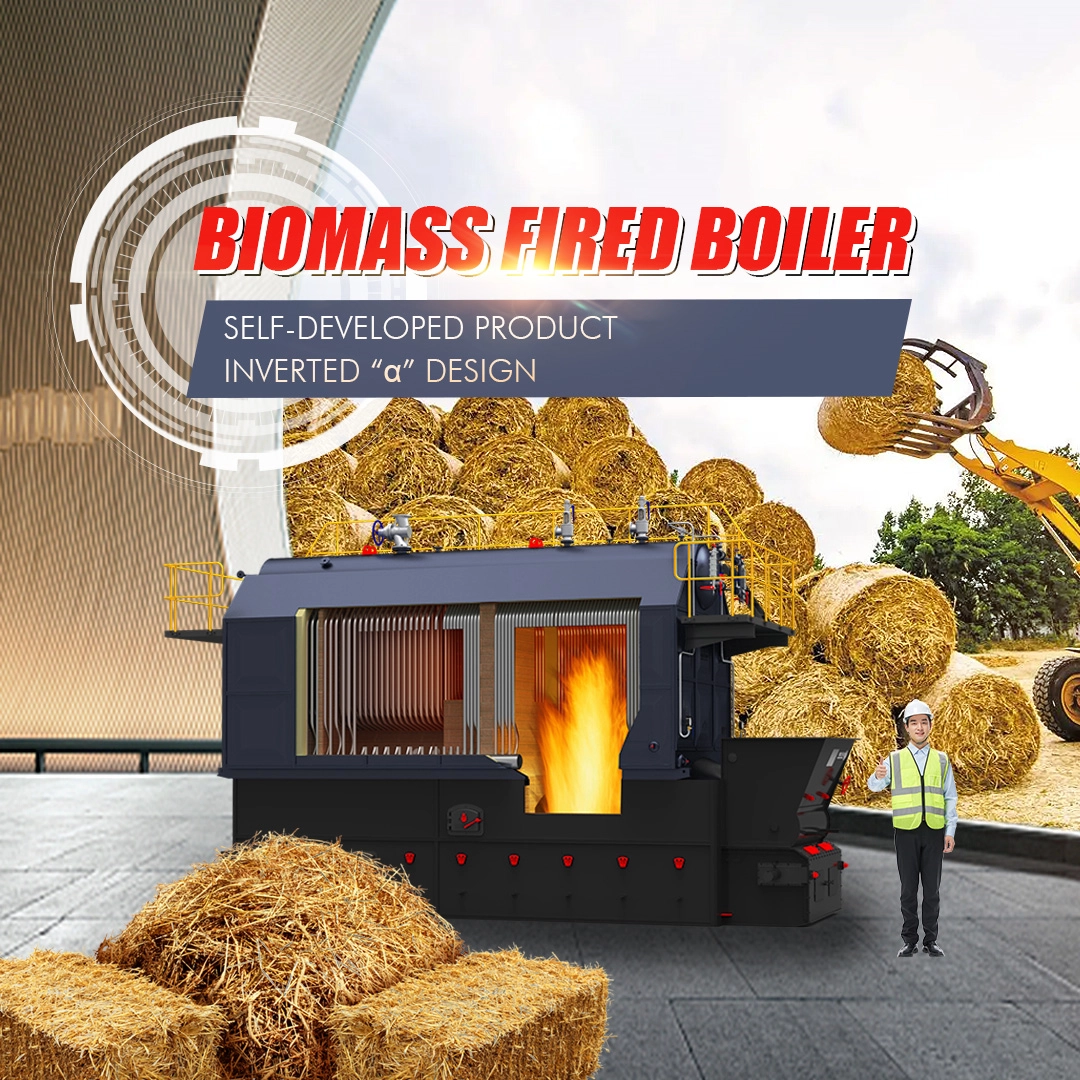

A biomass boiler system, in technical terms, is a heating system that utilizes biomass as a renewable energy source to generate heat. Biomass refers to organic materials, such as wood pellets, agricultural waste, or dedicated energy crops, which are used as fuel in the boiler system.

FANGKUAI, as a global leader in boiler technology, has made significant strides in developing innovative biomass boiler systems that are highly efficient and environmentally friendly. Our biomass boilers are equipped with advanced combustion technology to ensure optimal conversion of biomass into heat energy, minimizing harmful emissions and maximizing energy efficiency.

Components of a Biomass Fuel Feeding System

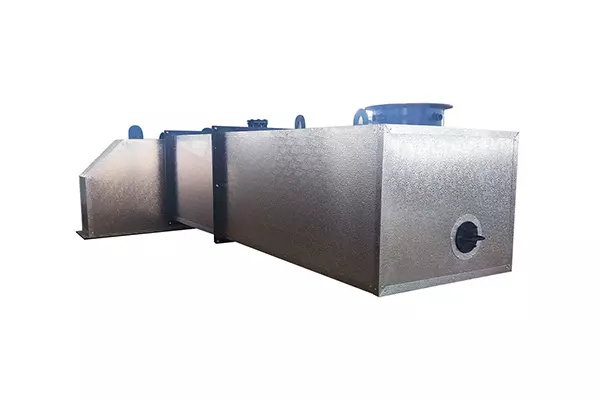

Fuel Storage Silos

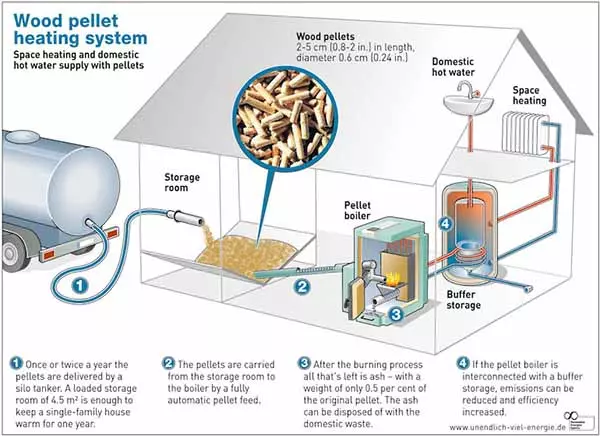

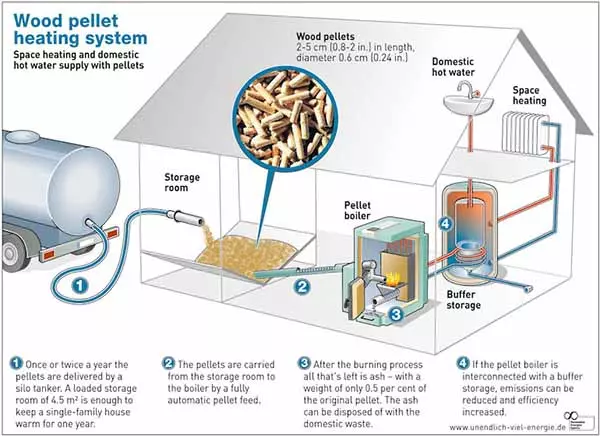

Companies use fuel storage silos to store bulk biomass fuel supplies. These silos come in various sizes, constructed from concrete, steel, or aluminum, tailored to specific requirements. Depending on the application, the silos can be situated either indoors or outdoors.

Fuel Feed Augers

Fuel feed augers play a crucial role in transporting biomass fuel from storage silos to the boiler grate for combustion. Augers utilize a screw mechanism that propels the fuel through a tube or channel towards the boiler.

Fuel Distributor

The fuel distributor ensures an even distribution of fuel across the boiler grate. This can involve a rotating arm moving across the grate for uniform fuel distribution, or a stationary distribution system can be employed.

Fuel Grate

Energy production begins on the fuel grate, where biomass fuel undergoes combustion. The design of the grate varies based on the specific fuel type being burned.

Control System

The biomass fuel feeding system is effectively operated and monitored through a control system. This system can incorporate automatic controls that regulate the fuel flow rate in response to the boiler’s load.

Advantages of a Biomass Fuel Feeding System

Biomass fuel feeding systems offer several advantages over traditional fossil fuel systems:

- Biomass fuel is a renewable resource that is available locally, reducing dependence on fossil fuels and reducing transportation emissions.

- Biomass fuel is environmentally friendly, with a low carbon footprint and minimal emissions.

- Biomass fuel systems can provide cost savings over time when compared to fossil fuel systems.

- Biomass fuel is a flexible fuel that can be used in a variety of applications, including industrial, commercial, and residential.

How to provide fuel for biomass boiler?

To provide fuel for a biomass boiler, several methods can be utilized. One common approach is through the use of a fuel storage and handling system. This system typically includes components such as fuel storage silos or containers, conveyors or augers for transporting the fuel, and equipment for unloading and feeding the fuel into the boiler.

The specific design and configuration of the fuel storage and handling system may vary depending on the type and characteristics of the biomass fuel being used. For instance, wood pellets may require a different handling system compared to agricultural waste or dedicated energy crops.

Grate boilers find widespread application in biomass combustion and exhibit the capacity to accommodate an array of fuel types, encompassing wood fuels, coal, waste fuels, peat, and even straw. Within these boilers, a grate mechanism takes center stage, facilitating the fuel’s introduction onto the grate. This movement can be governed through adjustable gates or the manipulation of the fuel movement speed positioned below the gate. As the fuel traverses the grate, combustion occurs, engendering heat that powers the boiler.

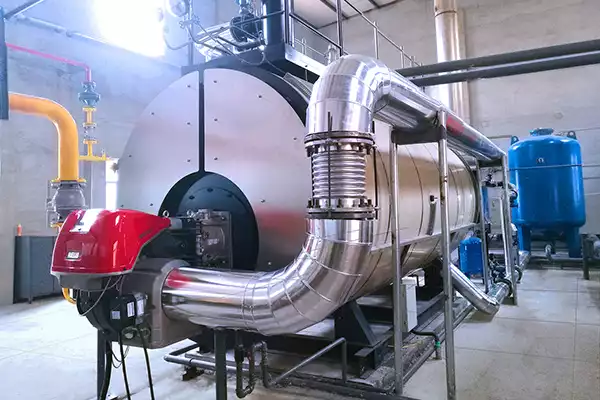

What is the process flow of biomass boiler?

The biomass boiler process consists of a series of distinct stages. To begin with, biomass fuel, encompassing materials such as wood pellets or agricultural waste, is initially stored in a dedicated fuel storage silo or container. Following this, the fuel is efficiently conveyed to the boiler using conveyors or augers, streamlining the process and ensuring a consistent fuel supply.

Inside the boiler, the biomass fuel undergoes combustion, thereby releasing heat energy. This heat is then harnessed to convert water into steam through a steam-water system. The process begins with water heating, followed by evaporation, and ultimately superheating, all powered by the energy derived from combustion. Essential components encompass tubes, pipes, valves, and diverse fittings.

The steam generated serves a multitude of purposes, including building heating, water heating, or even electricity generation by means of steam turbines. Furthermore, specific biomass boilers can employ thermochemical techniques to manufacture liquid or gaseous fuels such as renewable diesel, methane, or even renewable jet fuel.

Designing the Biomass Fuel Feeding System

Now, let’s embark on the journey of designing a biomass fuel feeding system that seamlessly integrates with your boiler setup. The cornerstone of this process is determining your fuel storage requirements and capacity. Accurate calculations prevent interruptions in fuel supply and guarantee your system’s reliability.

Fuel handling equipment plays a pivotal role in this system. From screw conveyors that ensure a consistent feed rate to hoppers equipped with agitators that prevent bridging, your choice impacts the overall efficiency. Tailor your selection to suit your needs, whether it’s precise delivery or preventing fuel clogs.

At the core of the system rests the fuel delivery mechanism, a pivotal element in sustaining continuous boiler operation. Consider it akin to a symphony – the delivery system’s precision orchestrates each note in perfect harmony, ensuring a seamless performance.

Implementing the Biomass Fuel Feeding System

With the design in place, it’s time to bring your biomass fuel feeding system to life. Proper site preparation is paramount, shielding your equipment from the elements and ensuring safety for both operators and equipment. Mother Nature can be unpredictable, but a well-prepared site can weather any storm.

The installation process involves configuring fuel storage and handling equipment. This step requires attention to detail – every connection, every setting matters. The components must work in tandem, like pieces of a puzzle coming together to form the big picture.

Connecting the fuel delivery system to the boiler is the moment of truth. Compatibility is key here, ensuring that the feed system seamlessly integrates with the boiler. As you make these connections, envision the energy flow – a continuous dance between the fuel and the boiler, choreographed for optimum efficiency.

Conclusion

Biomass fuel feeding systems are an important part of any biomass boiler system. They allow for the efficient and reliable transfer of biomass fuels from storage to the boiler for combustion. The advantages of biomass fuel systems make them an attractive alternative to traditional fossil fuel systems. With the increasing demand for renewable energy sources, biomass fuel systems will continue to grow in popularity and become a more common sight in industrial, commercial, and residential settings.

Get FREE Local Boiler Quotes today

Get FREE Local Boiler Quotes today

View Reviews of our Customer

"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"I am very impressed with the quality of Fangkuai's hot water boiler. It is built to last and has exceeded my expectations. The installation process was also very smooth and the customer service was excellent. The hot water boiler is very easy to operate and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's hot water boilers."

Jack

Australia"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China