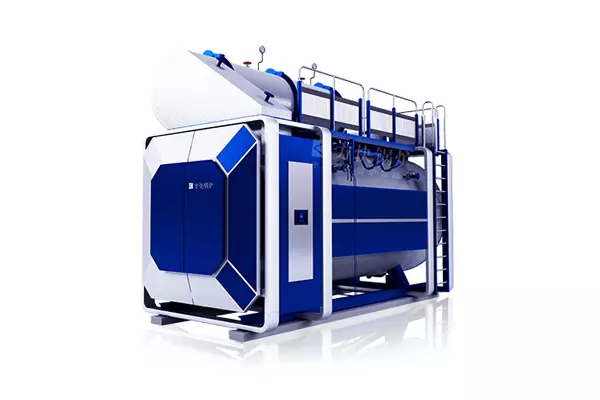

Waste heat boilers play a crucial role in industrial settings by converting residual heat into valuable steam. This waste heat boiler steam can be applied across various industrial applications, offering significant energy savings and promoting sustainable practices. Whether it’s used in power generation, heating, or cooling systems, the steam generated from waste heat boilers helps industries reduce fuel consumption, lower operating costs, and improve overall efficiency.

In this article, we will explore the benefits, key applications, and energy-saving potential of steam generated from waste heat boilers, along with best practices to maximize its use.

What is a Waste Heat Boiler and How Does It Work?

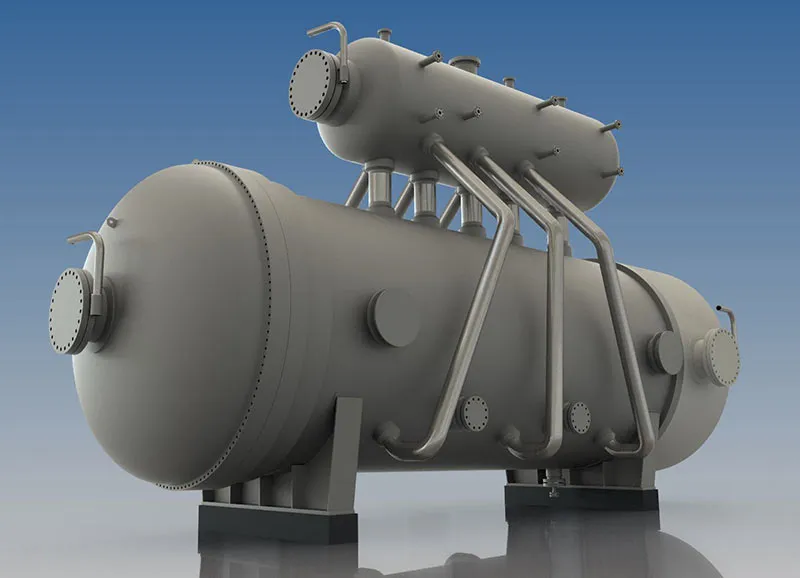

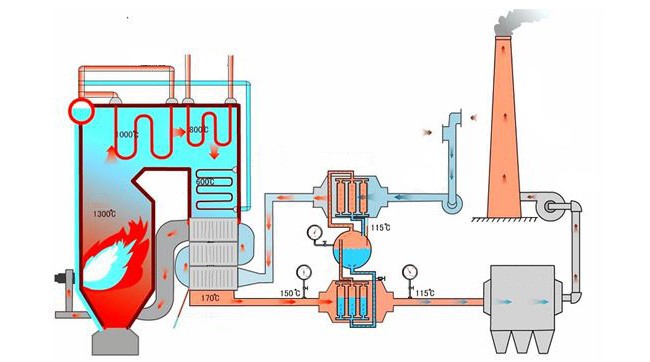

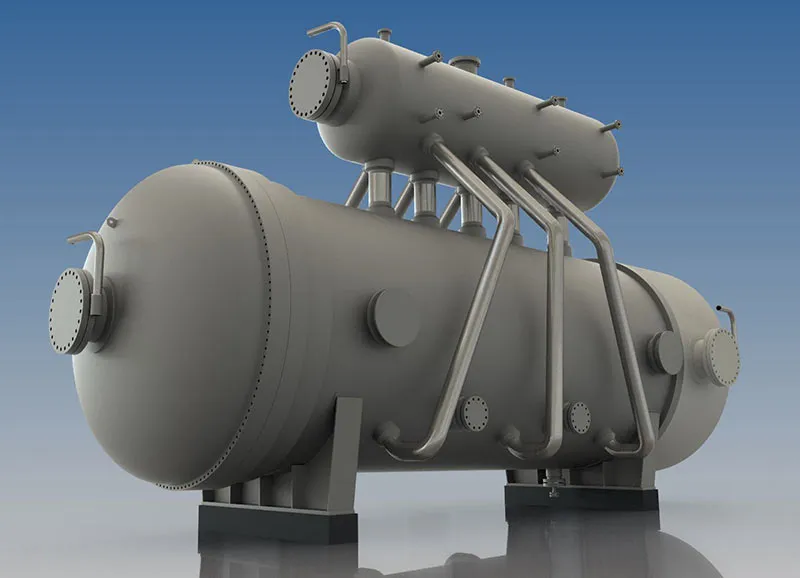

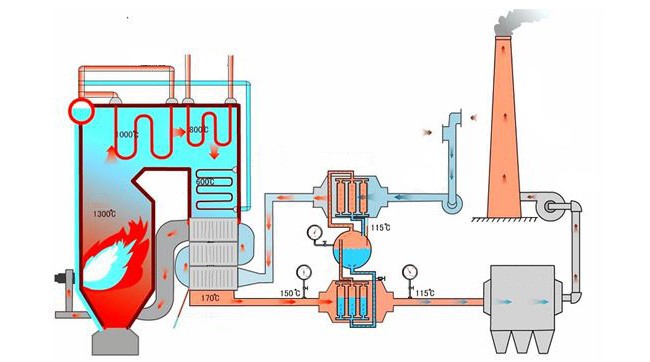

A waste heat boiler (WHB) is designed to recover heat from industrial processes, typically from exhaust gases emitted by equipment like furnaces, turbines, or engines. Instead of allowing this heat to escape into the environment, a WHB captures it and uses it to generate steam, turning what would have been wasted heat into usable energy.

Here’s a simplified breakdown of how a waste heat boiler works:

- Heat Source: Industrial processes produce exhaust gases that are typically released into the atmosphere. These gases carry significant thermal energy.

- Heat Transfer: In a WHB, this thermal energy is transferred to water or another heat-transfer fluid.

- Steam Generation: As the water absorbs heat, it converts into steam, which can be used for various applications.

By capturing waste heat and converting it into steam, waste heat boilers help industries increase energy efficiency and reduce emissions, which supports more environmentally friendly operations.

Top Benefits of Steam Generated from Waste Heat Boilers

Utilizing steam generated from waste heat boilers offers several advantages, helping industries improve their overall operational efficiency. Some of the key benefits include:

- Energy Efficiency: WHBs maximize energy recovery by utilizing otherwise wasted heat to generate steam. This reduces the need for additional fuel sources.

- Cost Savings: By utilizing residual heat, industries can reduce their fuel consumption, leading to lower energy bills and operating costs.

- Environmental Impact: Recovering waste heat helps reduce greenhouse gas emissions by cutting down the need to burn fuel to produce steam, contributing to cleaner industrial processes.

- Increased Productivity: With an efficient steam supply, processes requiring heat can operate continuously without interruptions for fuel replenishment.

- Sustainability: Reducing energy waste and leveraging renewable steam sources supports corporate social responsibility (CSR) initiatives and helps meet emissions regulations.

Main Industrial Applications of Steam from Waste Heat Boilers

The steam generated by waste heat boilers is highly versatile and can be used in a variety of industrial applications. Some of the most common uses include:

- Power Generation: Steam from waste heat boilers can drive turbines that generate electricity, either for the plant itself or for export to the grid.

- Process Heating: Many manufacturing processes require heat at different stages. Waste heat boiler steam is often used for drying, curing, or in chemical processing.

- Space Heating: In colder climates, steam is used to heat workspaces, office buildings, or entire industrial complexes.

- Cooling and Refrigeration Systems: Waste heat steam can be used in absorption chillers to produce chilled water for cooling systems, further enhancing energy efficiency.

- Desalination and Water Treatment: In water-scarce regions, waste heat steam is used in desalination processes to convert seawater into fresh water.

- Petrochemical Industry: Steam generated from waste heat boilers is vital in refining processes and in driving chemical reactions within the petrochemical sector.

Boosting Energy Efficiency and Reducing Costs with Waste Heat Boiler Steam

The energy-efficient nature of waste heat boiler steam is one of the key reasons why industries invest in these systems. Traditional boiler systems require additional fuel to generate steam, which can lead to increased energy costs. In contrast, waste heat boilers generate steam from residual heat, effectively recycling energy that would otherwise be lost.

Here are the key ways in which waste heat boiler steam boosts energy efficiency and reduces costs:

- Lower Fuel Expenses: By relying on waste heat, industries reduce their dependency on purchased fuels, leading to immediate savings.

- Decreased Maintenance Costs: Using waste heat reduces wear and tear on primary boilers, lowering the frequency and cost of maintenance.

- Minimized Downtime: Efficient steam recovery ensures continuous process operations, reducing the need for downtime and increasing overall productivity.

Driving Sustainability with Waste Heat Boiler Steam

With sustainability becoming a central focus for modern industries, waste heat boiler steam plays a crucial role in reducing environmental impact:

- Reduction in Carbon Footprint: By recovering and utilizing waste heat, industries cut down on fossil fuel consumption, leading to reduced greenhouse gas emissions and a smaller carbon footprint.

- Efficient Resource Use: Waste heat boilers turn what would have been wasted heat into a useful product, ensuring resources are used to their fullest potential.

- Meeting Regulatory Standards: As energy use and emissions regulations become more stringent, waste heat recovery helps businesses meet these requirements and avoid fines or penalties.

- Enhanced Public Perception: Operating sustainably not only benefits the environment but also improves public and investor perception, particularly as more consumers demand environmentally responsible business practices.

Innovative Industrial Uses of Waste Heat Boiler Steam

Industries are increasingly exploring innovative ways to harness waste heat boiler steam for enhanced energy efficiency and sustainability:

- District Heating: Some cities use waste heat boiler steam to provide district heating, distributing heat to homes and businesses from a central industrial plant.

- Hybrid Power Systems: Waste heat boilers can be integrated with renewable energy sources like solar, wind, or geothermal power to create hybrid systems that offer a more sustainable energy solution.

- Cogeneration: Steam from waste heat boilers is often used in combined heat and power (CHP) systems, providing both electricity and heat for industrial plants or surrounding areas.

- Advanced Desalination Technologies: Waste heat boiler steam is increasingly being used in innovative desalination processes, reducing the energy demand for converting seawater into potable water.

Best Practices for Efficient Waste Heat Boiler Operation and Maintenance

To maximize the performance and longevity of waste heat boilers, industries should follow these best practices for operation and maintenance:

- Regular Inspection: Routinely check the boiler’s heat exchange surfaces, steam output, and control systems to prevent efficiency losses and safety hazards.

- Proper Cleaning: Keep the heat transfer surfaces free of soot and debris to ensure efficient heat exchange and optimal steam production.

- Monitoring Flue Gas: Continuously measure flue gas composition to adjust the air-to-fuel ratio and ensure complete combustion for maximum energy recovery.

- Boiler Tuning: Periodic tuning of the boiler system ensures all components operate at peak efficiency and prevents unnecessary fuel consumption.

Conclusion

Waste heat boiler steam is a powerful tool for industries aiming to improve their energy efficiency, reduce operating costs, and lower their environmental impact. By recovering heat that would otherwise be wasted, industries can create a more sustainable and efficient operation. As energy regulations tighten and sustainability goals become more prominent, the role of waste heat boilers will continue to grow, helping industries transition toward greener, more energy-efficient solutions.

View Reviews of our Customer

"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK