Biomass energy, a renewable source with zero carbon dioxide emissions, is increasingly recognized as crucial for sustainable energy transformation. In this context, boilers, essential for thermal energy conversion in industrial processes, are gaining prominence. Biomass-fueled boilers, in particular, have significant market potential, especially in environments where coal combustion is restricted. However, many biomass boilers suffer from low thermal efficiency. This article analyzes the reasons for this inefficiency and offers practical suggestions for improvement.

Causes of Low Thermal Efficiency

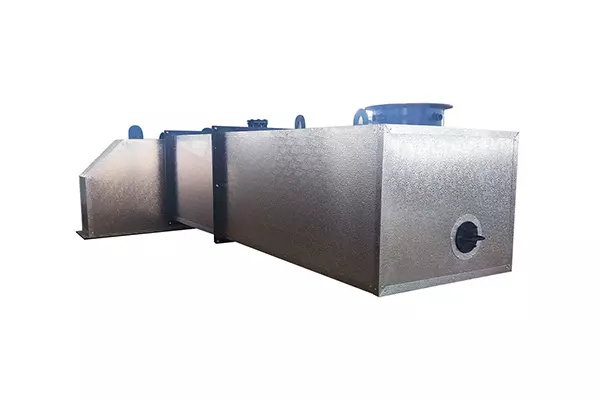

1. Unreasonable Boiler Structure

The design of some biomass boilers includes poor air chamber sealing, leading to air cross-flow and leakage, which increases heat loss and reduces thermal efficiency. Traditional “eight”-shaped furnace structures are often inadequate for the segmented combustion required by biomass boilers, resulting in inefficient fuel combustion.

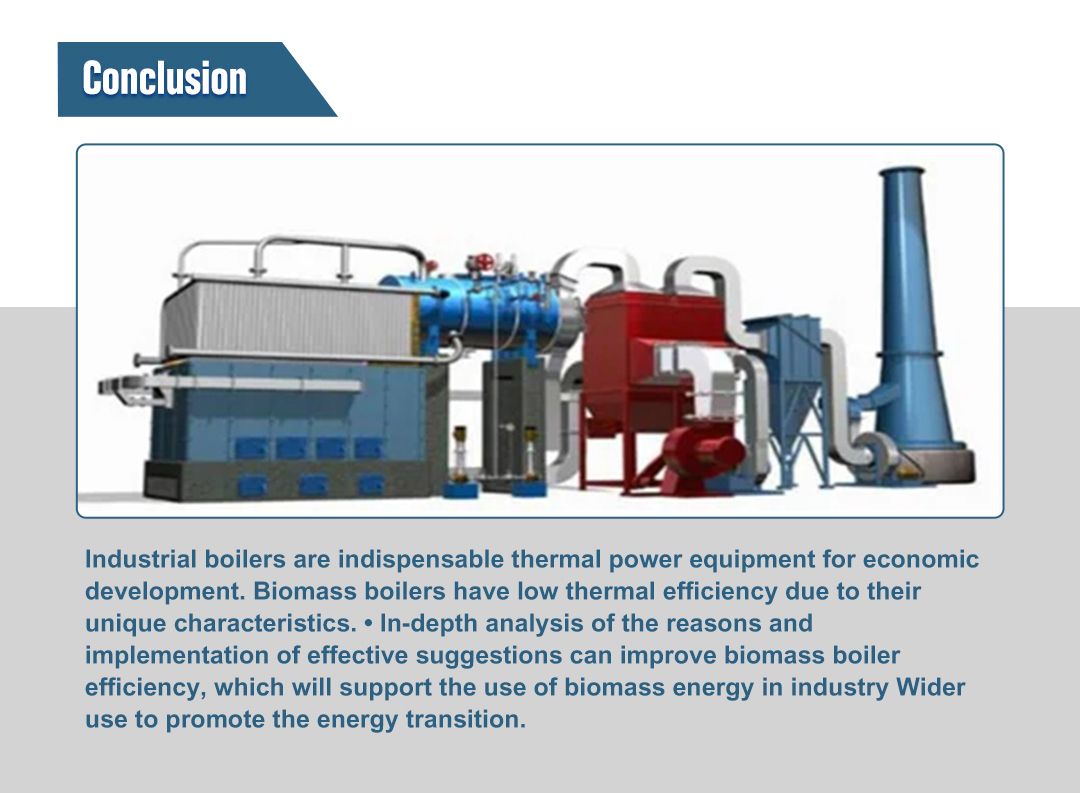

2. Long-term Low-load Operation

Operating boilers at low loads for extended periods increases heat loss and reduces efficiency. This often occurs when boilers with excessive capacity are purchased or when operators fail to monitor and adjust the boiler’s operating conditions, keeping the load outside the economic range.

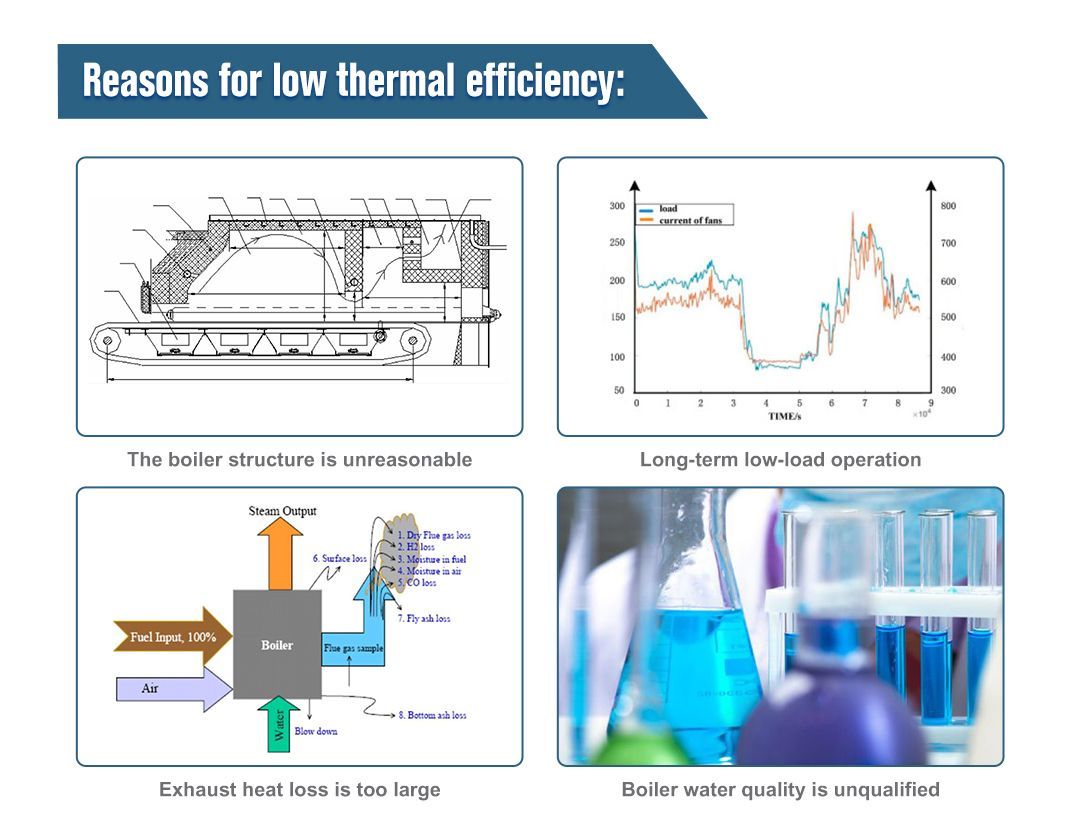

3. High Exhaust Smoke Heat Loss

Heat loss through exhaust smoke is a significant factor, influenced by exhaust temperature and excess air coefficient. High values in these parameters lead to reduced thermal efficiency, often due to improper air distribution, system leaks, and outdated air adjustment methods.

4. Unqualified Boiler Water Quality

Poor boiler water quality leads to scale formation, increasing heat transfer resistance and reducing efficiency. This issue stems from inadequate water quality management, mismatched water treatment equipment, and insufficiently trained personnel.

Suggestions for Improving Boiler Thermal Efficiency

1. Enhance Boiler Design and Manufacturing

Optimizing the boiler structure to effectively utilize flue gas waste heat and increasing the heating surface or using multiple heat exchange methods can reduce exhaust gas temperature. Improving the thermal insulation and ensuring good sealing and insulation of all boiler components can significantly reduce heat loss.

2. Implement Energy-saving Management Systems

Energy conservation and environmental protection managers should have clear responsibilities. Boiler operating parameters should be included in daily inspections, and abnormal conditions should be promptly addressed. Establishing a fuel inspection system to ensure the biomass pellets match the boiler design is also crucial.

3. Improve Technical Skills of Boiler Operators

Providing energy-saving training and conducting regular combustion and adjustment tests for operators can enhance their ability to monitor and adjust boiler conditions. Adopting a thin biomass fuel layer, low-wind operation mode, and adjusting grate speed based on load changes can optimize operating conditions.

Conclusion

Industrial boilers are vital in the national economy, especially biomass boilers, which present unique challenges in achieving high thermal efficiency. By addressing the causes of low efficiency and implementing the suggested improvements, the overall efficiency of biomass boiler s can be significantly enhanced. This not only promotes the efficient use of energy but also supports sustainable development. These improvements will help expand the application of biomass energy in industrial settings, contributing to a successful energy transition.

View Reviews of our Customer

"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"I am very impressed with the quality of Fangkuai's hot water boiler. It is built to last and has exceeded my expectations. The installation process was also very smooth and the customer service was excellent. The hot water boiler is very easy to operate and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's hot water boilers."

Jack

Australia"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico