Industrieller Diesel-Dampfkessel zu verkaufen

Effiziente und zuverlässige elektrische Dampfkessel

Hocheffiziente Biomasse-Dampfkessel

Zuverlässige und effiziente kohlebefeuerte Dampfkessel

Diesel-Warmwasserkessel zu verkaufen

Gewerbliche Ölkessel: Merkmale, Vorteile, und Top-Marken

Hochwertige kohlebefeuerte Warmwasserkessel

Zuverlässige und effiziente Biomasse-Heißwasserkessel

Biomasse-Dampferzeuger - Effiziente und nachhaltige Energielösung

Hochleistungs-Elektrodampferzeuger für den industriellen Einsatz

Hocheffizienter Gasdampferzeuger

Leistungsstarker und effizienter Dieseldampferzeuger für den industriellen Einsatz

Sparen Sie Energie und reduzieren Sie Kosten mit dem Fangkuai Boiler Energy Saver

Kesselentlüfter: Die effiziente Lösung für Dampfsysteme

Fangkuais Kesselbrenner: Die ultimative Lösung für hohe Effizienz und niedrige Emissionen

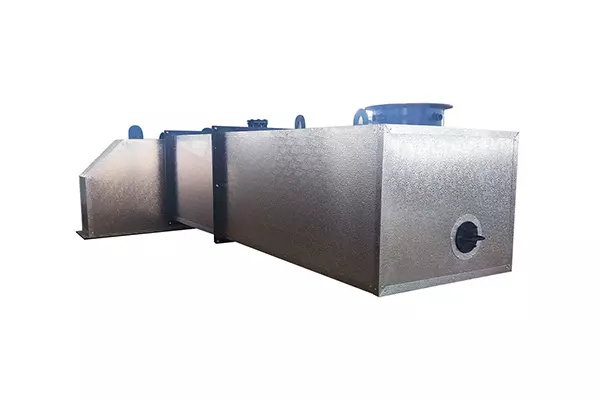

Boiler Warmwasserspeicher | Zuverlässige und bequeme Lösung für Warmwasserbedarf

Zhengzhou Fangkuai Boiler Sales Co., GmbH. ist eine Tochtergesellschaft der Fangkuai Boiler Company, mainly responsible for the domestic and foreign trade of Fangkuai Boiler.Fangkuai Headquarters Base has a single-building R&D center, ein voll funktionsfähiges Labor und zwei Fertigungsstätten Pflanzen, mit einer Produktionsfläche von 120.000 Quadratmetern. Es ist das führende Unternehmen in China mit Verarbeitungskapazitäten für die Kesselautomatisierung, und seine Produkte werden zu vielen exportiert Länder und Regionen.

vSehen Sie sich die Bewertungen unserer Kunden an

"Der Dampfkessel von Fangkuai ist perfekt für meinen Lebensmittelverarbeitungsbetrieb. Es erfüllt alle unsere Anforderungen und ist sehr zuverlässig. Die Qualität der Materialien und die Konstruktion des Kessels sind außergewöhnlich. Außerdem ist es sehr einfach zu bedienen und zu warten, Das hat uns geholfen, Zeit und Geld bei der Wartung zu sparen. Ich kann die Dampfkessel von Fangkuai jedem wärmstens empfehlen, der zuverlässige Heizlösungen benötigt."

Json

Brasilien"Der Kundenservice bei Fangkuai ist erstklassig. Sie halfen mir bei der Auswahl des perfekten Kessels für meine Bedürfnisse und boten während des gesamten Prozesses großartige Unterstützung. Der Installationsprozess verlief auch sehr reibungslos und der Kessel hat meine Erwartungen übertroffen. Es ist sehr einfach zu bedienen und zu warten, und die Energieeffizienz ist bemerkenswert. Ich kann die Produkte von Fangkuai jedem wärmstens empfehlen, der zuverlässige und effiziente Heizlösungen benötigt."

Juan

Mexiko"Ich bin sehr beeindruckt von der Qualität des Heißwasserboilers von Fangkuai. Es ist für die Ewigkeit gebaut und hat meine Erwartungen übertroffen. Auch die Installation verlief reibungslos und der Kundenservice war ausgezeichnet. Der Warmwasserboiler ist sehr einfach zu bedienen und zu warten, und die Energieeffizienz ist bemerkenswert. Ich kann die Heißwasserboiler von Fangkuai sehr empfehlen."

Jack

Australien"Der Heißwasserboiler von Fangkuai ist erstaunlich. Es heizt schnell und effizient auf, und das Wasser bleibt lange heiß. Wir hatten nie Probleme damit und es hat unsere täglichen Abläufe erheblich verbessert. Auch die Installation verlief reibungslos und der Kundenservice war ausgezeichnet. Ich kann die Heißwasserboiler von Fangkuai sehr empfehlen."

Sarah

Kanada"Der Kundenservice bei Fangkuai ist erstklassig. Sie halfen mir bei der Auswahl des perfekten Kessels für meine Bedürfnisse und boten während des gesamten Prozesses großartige Unterstützung. Der Installationsprozess verlief auch sehr reibungslos und der Kessel hat meine Erwartungen übertroffen. Es ist sehr einfach zu bedienen und zu warten, und die Energieeffizienz ist bemerkenswert. Ich kann die Produkte von Fangkuai jedem wärmstens empfehlen, der zuverlässige und effiziente Heizlösungen benötigt."

Juan

Mexiko"Wir verwenden den Fangkuai-Thermalölkessel seit Jahren für unsere Chemieanlage und er hat uns nie im Stich gelassen. Der Kessel ist sehr langlebig und hält rauen Bedingungen stand. Außerdem ist es sehr einfach zu bedienen und zu warten, Das hat uns geholfen, Zeit und Geld bei der Wartung zu sparen. Die Thermalölkessel von Fangkuai sind erstklassig und ich kann sie jedem wärmstens empfehlen, der zuverlässige Heizlösungen benötigt."

Chang

China"Ich habe für meine Fabrik einen Fangkuai-Dampfkessel gekauft, der seit Monaten einwandfrei funktioniert. Die Qualität der Materialien und die Konstruktion des Kessels sind beeindruckend. Es ist auch sehr energieeffizient, was uns geholfen hat, Geld bei unseren Energierechnungen zu sparen. Ich kann die Produkte von Fangkuai jedem wärmstens empfehlen, der zuverlässige und effiziente Heizlösungen benötigt."

John

USA"Die Zusatzausrüstung von Fangkuai hat mein Kesselsystem noch besser gemacht. Die Qualität der Ausrüstung ist außergewöhnlich und die Preise sind sehr vernünftig. Die Ausrüstung hat dazu beigetragen, die Effizienz und Leistung meines Kesselsystems zu verbessern, was zu erheblichen Kosteneinsparungen geführt hat. Ich kann die Zusatzausrüstung von Fangkuai jedem wärmstens empfehlen, der hochwertiges Kesselzubehör benötigt."

Maryk

Vereinigtes Königreich"Wir verwenden den Fangkuai-Thermalölkessel seit Jahren für unsere Chemieanlage und er hat uns nie im Stich gelassen. Der Kessel ist sehr langlebig und hält rauen Bedingungen stand. Außerdem ist es sehr einfach zu bedienen und zu warten, Das hat uns geholfen, Zeit und Geld bei der Wartung zu sparen. Die Thermalölkessel von Fangkuai sind erstklassig und ich kann sie jedem wärmstens empfehlen, der zuverlässige Heizlösungen benötigt."

Chang

China