Hervir agua es un proceso fundamental tanto en la cocina diaria como en diversas aplicaciones industriales.. Una creencia común sugiere que agregar sal al agua puede hacer que hierva más rápido.. Este artículo explora esta afirmación en el contexto de calderas industriales y proporciona consejos prácticos sobre el uso seguro y eficaz de la sal en estos sistemas..

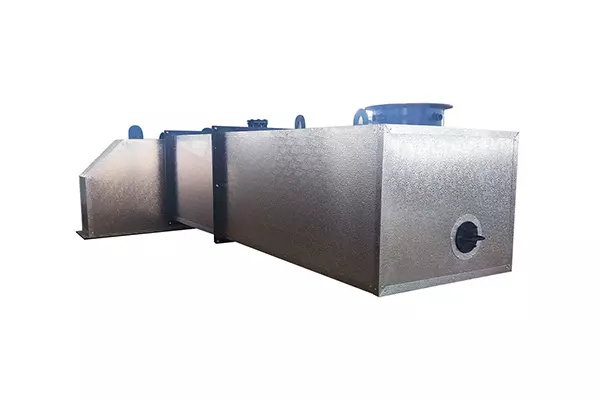

Caldera de vapor de leña

Caldera de vapor de leña

Guías & Cómo hacerlo

5 Pasos para agregar sal de forma segura a un Caldera de vapor

Consulte las pautas del fabricante: Antes de agregar cualquier sustancia a su caldera de vapor, Siempre consulte las pautas del fabricante para garantizar la compatibilidad y la seguridad..

Mida la cantidad adecuada de sal: Utilice medidas precisas para evitar el exceso de sal, que puede provocar corrosión o incrustaciones.. Típicamente, Se recomienda una cantidad controlada y mínima..

Disolver la sal en agua: Disolver previamente la sal en una pequeña cantidad de agua antes de añadirla a la caldera.. Esto ayuda a distribuir uniformemente la sal y evitar que se formen grumos..

Agregue gradualmente la solución salina.: Agregue lentamente la solución salina al agua de la caldera para evitar reacciones químicas repentinas que puedan afectar el funcionamiento de la caldera..

Monitorear los parámetros de la caldera: Después de agregar sal, monitorear continuamente los parámetros de la caldera, como la presión, temperatura, y niveles de agua, para garantizar un funcionamiento estable.

Cómo medir correctamente la sal de su caldera?

La medición precisa es crucial al agregar sal a su caldera. Utilice una báscula digital para pesar la sal con precisión.. La cantidad variará dependiendo de la capacidad de la caldera y del efecto deseado.. Para aplicaciones industriales, La concentración generalmente se mantiene baja para evitar efectos adversos en el material de la caldera..

La guía definitiva para mejorar la eficiencia de la caldera con sal

Aunque agregar sal al agua no acelera el proceso de ebullición., puede ayudar de otras maneras:

Prevención de la formación de incrustaciones: La sal puede ayudar a reducir la formación de incrustaciones en la caldera., que puede mejorar la eficiencia de la transferencia de calor.

Control de corrosión: Ciertas sales pueden ayudar a controlar el nivel de pH del agua., evitando así la corrosión.

Eficiencia de mantenimiento: Los niveles de sal gestionados adecuadamente pueden prolongar la vida útil de la caldera al reducir la frecuencia del mantenimiento..

Consejos para controlar los niveles de agua al agregar sal a su caldera

Controles regulares: Verifique continuamente los niveles de agua para asegurarse de que estén dentro del rango recomendado.

Sistemas automatizados: Utilice sistemas automatizados de monitoreo del nivel de agua para mantener niveles óptimos y evitar errores manuales.

Adiciones de saldo: Asegúrese de que la adición de sal no altere drásticamente los niveles de agua o el equilibrio químico..

Lo que necesita saber antes de agregar sal a su caldera

Elevación del punto de ebullición: Entiende que agregar sal aumenta el punto de ebullición del agua., lo que significa que tarda más en hervir.

Riesgos de corrosión: Las altas concentraciones de sal pueden acelerar la corrosión., por eso es importante agregar sal con precaución.

Tipo de caldera: Diferentes calderas pueden responder de manera diferente a la sal.; Considere siempre el tipo y modelo específico de su caldera..

Preguntas

¿Agregar sal es la clave para que el agua hierva más rápido en una caldera de vapor??

No, Agregar sal no es la clave para hervir más rápido. De hecho, aumenta el punto de ebullición del agua, Requiere más energía y tiempo para alcanzar la ebullición..

¿La sal realmente hará que el agua de su caldera hierva más rápido??

No, La sal no hará que el agua de la caldera hierva más rápido.. Aumentará el punto de ebullición., potencialmente haciendo que el proceso sea más lento.

¿Puede la sal tener un impacto en la velocidad de ebullición del agua de la caldera??

Sí, pero no de la manera que podrías esperar. La sal aumenta el punto de ebullición del agua., lo que significa que en realidad puede reducir la velocidad de ebullición.

¿Debería considerar agregar sal a su caldera de vapor para una ebullición más rápida??

No, agregar sal para hervir más rápido es ineficaz. Las razones principales para agregar sal al agua de la caldera deben estar relacionadas con el mantenimiento y la eficiencia., no velocidad.

¿Qué efecto tiene la sal sobre el punto de ebullición del agua de la caldera??

La sal eleva el punto de ebullición del agua debido al fenómeno conocido como elevación del punto de ebullición. Esto requiere que el agua alcance una temperatura más alta antes de que hierva..

costo de la caldera de biomasa

Listas

10 Conceptos erróneos comunes sobre la adición de sal a las calderas de vapor

Acelera la ebullición: Incorrecto; aumenta el punto de ebullición.

Mejora la transferencia de calor: Parcialmente cierto, pero específico del contexto.

Seguro para todas las calderas: No siempre; consultar pautas.

Necesario para todos los sistemas: Depende del tipo de caldera.

Previene toda corrosión: Sólo ciertos tipos y condiciones..

Aumenta la eficiencia universalmente: No es una declaración general.

Se puede agregar en cualquier momento: El momento y el método son cruciales.

Elimina las necesidades de mantenimiento: Reduce, pero no elimina.

No hay necesidad de monitoreo: El seguimiento continuo es esencial.

Funciona con todo tipo de agua: Depende de la química del agua..

La parte superior 5 Beneficios de agregar sal al agua de su caldera

Previene la formación de incrustaciones

Controla la corrosión

Mejora la eficiencia de la transferencia de calor

Reduce la frecuencia de mantenimiento

Mantiene el equilibrio del pH

8 Razones por las que deberías (o no debería) Agregue sal a su caldera

Debería: Previene la formación de incrustaciones.

Debería: Ayuda a controlar la corrosión..

Debería: Mejora la eficiencia de la transferencia de calor..

Debería: Mantiene la química del agua..

No debería: Puede aumentar el punto de ebullición.

No debería: Riesgo de exceso de sal y corrosión..

No debería: Puede requerir más energía para hervir.

No debería: No apto para todos los tipos de calderas..

Lo que se debe y lo que no se debe hacer al usar sal en su caldera de vapor

Hacer: Consulta las pautas del fabricante..

Hacer: Medir con precisión.

Hacer: Monitorear los parámetros de la caldera..

No: Agrega demasiada sal de una vez.

No: Ignorar cambios en el comportamiento de la caldera..

No: Utilice sal como solución rápida para los problemas de eficiencia.

15 Cosas a considerar antes de agregar sal al agua de su caldera

Tipo de caldera

Directrices del fabricante

Química del agua

Concentración de sal

Precisión de medición

Proceso de disolución

Método de suma

Sistemas de Monitoreo

Cambios en el punto de ebullición

Riesgos de corrosión

Prevención de formación de incrustaciones

Eficiencia de transferencia de calor

Requisitos de mantenimiento

Consumo de energía

Eficiencia general

Otros

La ciencia detrás de agregar sal a su caldera de vapor

Agregar sal al agua afecta su punto de ebullición debido a la propiedad coligativa conocida como elevación del punto de ebullición.. Cuando la sal se disuelve en agua, se disocia en iones, que interrumpen la formación de burbujas de vapor necesarias para la ebullición. Esta interrupción eleva el punto de ebullición., lo que significa que el agua requiere más energía térmica para comenzar a hervir.

Explorando los efectos de la sal sobre el agua hirviendo en calderas

En calderas industriales, El propósito principal de agregar sal no es acelerar la ebullición sino controlar la química del agua y prevenir la formación de incrustaciones y la corrosión.. El impacto práctico de la sal en el tiempo de ebullición es mínimo y a menudo se ve superado por los beneficios de un mejor mantenimiento de la caldera..

La sorprendente verdad sobre el uso de sal en la caldera

A pesar del mito común, Agregar sal al agua de la caldera no acelera el proceso de ebullición.. En cambio, eleva el punto de ebullición y requiere más energía para alcanzar la etapa de ebullición. Los beneficios de agregar sal radican en su capacidad para gestionar la química del agua y mejorar la longevidad de la caldera..

Un análisis completo de la adición de sal al agua de la caldera

Un análisis exhaustivo revela que agregar sal al agua de la caldera tiene varios beneficios, incluida la prevención de incrustaciones, controlando la corrosión, y mantener una transferencia de calor eficiente. Sin embargo, Es fundamental añadir sal en cantidades controladas y controlar continuamente la caldera para garantizar un rendimiento óptimo y evitar efectos adversos..

Descubriendo los mitos y realidades de la sal en las calderas de vapor

El mito de que la sal acelera la ebullición es desmentido por la evidencia científica que demuestra que en realidad aumenta el punto de ebullición.. Las verdaderas ventajas de añadir sal residen en mejorar el mantenimiento y la eficiencia de la caldera, no en acelerar el proceso de ebullición. La comprensión y el manejo adecuados de la sal en el agua de la caldera pueden conducir a operaciones de caldera más efectivas y duraderas..

Conclusión

La afirmación de que agregar sal al agua hace que hierva más rápido es un mito. En el contexto de las calderas industriales, agregar sal en realidad aumenta el punto de ebullición, Requiere más energía para que el agua hierva.. Los principales beneficios de agregar sal al agua de la caldera incluyen prevenir la formación de incrustaciones., controlando la corrosión, y mejorar la eficiencia general. Al comprender y gestionar adecuadamente la adición de sal, se puede garantizar un rendimiento y una longevidad óptimos de la caldera.

Resumen

Agregar sal al agua aumenta su punto de ebullición, lo que significa que tarda más en hervir. En calderas industriales, Los efectos prácticos de la sal son significativos para el mantenimiento pero mínimos para la velocidad de ebullición.. Utilice métodos como optimizar el diseño de la caldera., aumento del aporte de calor, y precalentar agua para hervir más rápido. Este artículo proporciona claridad sobre el tema y ayuda a mejorar la eficiencia en aplicaciones industriales..

Caldera de vapor de leña

Caldera de vapor de leña

VVer opiniones de nuestro cliente

"Estoy muy impresionado con la calidad de la caldera de agua caliente de Fangkuai.. Está construido para durar y ha superado mis expectativas.. El proceso de instalación también fue muy sencillo y el servicio al cliente fue excelente.. La caldera de agua caliente es muy fácil de operar y mantener, y la eficiencia energética es notable. Recomiendo encarecidamente las calderas de agua caliente de Fangkuai."

Jacobo

Australia"La caldera de agua caliente de Fangkuai es increíble. Se calienta de forma rápida y eficiente., y el agua se mantiene caliente por mucho tiempo. Nunca hemos tenido ningún problema con él y ha mejorado significativamente nuestras operaciones diarias.. El proceso de instalación también fue muy sencillo y el servicio al cliente fue excelente.. Recomiendo encarecidamente las calderas de agua caliente de Fangkuai."

Sara

Canada"El servicio al cliente en Fangkuai es de primera categoría.. Me ayudaron a elegir la caldera perfecta para mis necesidades y me brindaron un gran apoyo durante todo el proceso.. El proceso de instalación también fue muy sencillo y la caldera ha superado mis expectativas.. Es muy fácil de usar y mantener., y la eficiencia energética es notable. Recomiendo encarecidamente los productos de Fangkuai a cualquiera que necesite soluciones de calefacción fiables y eficientes."

Juan

México"El servicio al cliente en Fangkuai es de primera categoría.. Me ayudaron a elegir la caldera perfecta para mis necesidades y me brindaron un gran apoyo durante todo el proceso.. El proceso de instalación también fue muy sencillo y la caldera ha superado mis expectativas.. Es muy fácil de usar y mantener., y la eficiencia energética es notable. Recomiendo encarecidamente los productos de Fangkuai a cualquiera que necesite soluciones de calefacción fiables y eficientes."

Juan

México"Estoy muy impresionado con la calidad de la caldera de agua caliente de Fangkuai.. Está construido para durar y ha superado mis expectativas.. El proceso de instalación también fue muy sencillo y el servicio al cliente fue excelente.. La caldera de agua caliente es muy fácil de operar y mantener, y la eficiencia energética es notable. Recomiendo encarecidamente las calderas de agua caliente de Fangkuai."

Jacobo

Australia"El generador de vapor de Fangkuai es perfecto para mi pequeña empresa. Es muy fácil de usar y requiere un mantenimiento mínimo.. También es muy eficiente energéticamente., que me ha ayudado a ahorrar dinero en mis facturas de energía. El servicio al cliente en Fangkuai también es excelente.. Son muy receptivos y siempre dispuestos a ayudar.. Recomiendo encarecidamente los generadores de vapor de Fangkuai."

ahmed

Egipto"La caldera de aceite térmico de Fangkuai es muy fácil de operar y mantener. Nos ha ayudado a ahorrar tiempo y dinero en mantenimiento., lo que ha supuesto un importante ahorro de costes. La calidad de los materiales y la construcción de la caldera son excepcionales. También es muy eficiente energéticamente., lo que nos ha ayudado a ahorrar dinero en nuestras facturas de energía. Recomiendo encarecidamente la caldera de aceite térmico de Fangkuai. ."

allen

Brasil"Estoy muy impresionado con la calidad de la caldera de agua caliente de Fangkuai.. Está construido para durar y ha superado mis expectativas.. El proceso de instalación también fue muy sencillo y el servicio al cliente fue excelente.. La caldera de agua caliente es muy fácil de operar y mantener, y la eficiencia energética es notable. Recomiendo encarecidamente las calderas de agua caliente de Fangkuai."

Jacobo

Australia"Llevamos años utilizando la caldera de aceite térmico Fangkuai para nuestra planta química y nunca nos ha defraudado.. La caldera es muy duradera y puede soportar condiciones adversas.. También es muy fácil de operar y mantener., lo que nos ha ayudado a ahorrar tiempo y dinero en mantenimiento. Las calderas de aceite térmico de Fangkuai son de primera y las recomiendo a cualquiera que necesite soluciones de calefacción confiables."

chang

Porcelana