- RUMAH

- INDUSTRI

- INDUSTRI

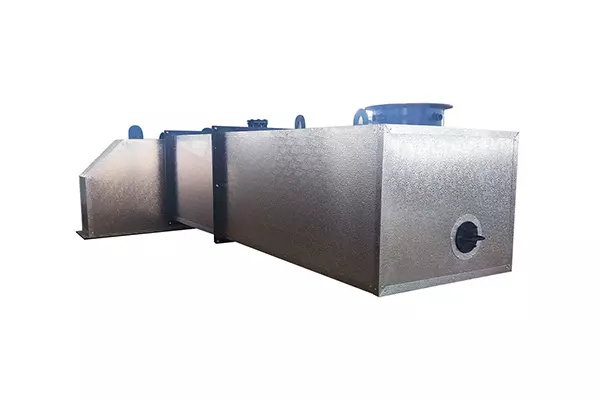

- Boiler Fang Kuai menawarkan sesuai permintaan, solusi steam modular untuk aplikasi industri dan komersial yang membutuhkan proses steam untuk panas, sterilisasi, pelembapan, dan banyak lagi.

- PRODUK

- KASUS GLOBAL

- TENTANG KAMI

- BERITA

- KONTAK

.jpg)

View Ulasan Pelanggan kami

"Peralatan bantu Fangkuai telah membuat sistem ketel saya menjadi lebih baik. Kualitas peralatannya luar biasa dan harganya sangat masuk akal. Peralatan tersebut telah membantu meningkatkan efisiensi dan kinerja sistem ketel saya, yang telah menyebabkan penghematan biaya yang signifikan. Saya sangat merekomendasikan peralatan bantu Fangkuai kepada siapa pun yang membutuhkan aksesori boiler berkualitas tinggi."

Maryk

Inggris"Layanan pelanggan di Fangkuai adalah yang terbaik. Mereka membantu saya memilih boiler yang sempurna untuk kebutuhan saya dan memberikan dukungan yang luar biasa selama proses berlangsung. Proses pemasangannya juga sangat lancar dan ketelnya melebihi ekspektasi saya. Sangat mudah digunakan dan dirawat, dan efisiensi energinya luar biasa. Saya sangat merekomendasikan produk Fangkuai kepada siapa pun yang membutuhkan solusi pemanasan yang andal dan efisien."

Juan

Meksiko"Saya membeli ketel uap Fangkuai untuk pabrik saya dan telah berfungsi dengan sempurna selama berbulan-bulan sekarang. Kualitas bahan dan konstruksi boiler sangat mengesankan. Ini juga sangat hemat energi, yang telah membantu kami menghemat uang untuk tagihan energi kami. Saya sangat merekomendasikan produk Fangkuai kepada siapa pun yang membutuhkan solusi pemanasan yang andal dan efisien."

Yohanes

Amerika Serikat"Pembangkit uap Fangkuai sangat bagus. Mereka sangat mudah digunakan dan membutuhkan perawatan minimal. Layanan pelanggan di Fangkuai juga luar biasa. Mereka sangat responsif dan selalu bersedia membantu. Efisiensi energi dari pembangkit uap juga luar biasa, yang telah membantu saya menghemat uang untuk tagihan energi saya. Saya sangat merekomendasikan generator uap Fangkuai."

Maria

Spanyol"Saya sangat terkesan dengan kualitas ketel air panas Fangkuai. Itu dibangun untuk bertahan dan telah melebihi harapan saya. Proses instalasi juga sangat lancar dan layanan pelanggan sangat baik. Ketel air panas sangat mudah dioperasikan dan dirawat, dan efisiensi energinya luar biasa. Saya sangat merekomendasikan boiler air panas Fangkuai."

Mendongkrak

Australia"Pembangkit uap dari Fangkuai sangat cocok untuk usaha kecil saya. Sangat mudah digunakan dan membutuhkan perawatan minimal. Ini juga sangat hemat energi, yang telah membantu saya menghemat uang untuk tagihan energi saya. Layanan pelanggan di Fangkuai juga luar biasa. Mereka sangat responsif dan selalu bersedia membantu. Saya sangat merekomendasikan generator uap Fangkuai."

Ahmad

Mesir"Steam boiler dari Fangkuai sangat cocok untuk usaha pengolahan makanan saya. Ini memenuhi semua persyaratan kami dan sangat dapat diandalkan. Kualitas bahan dan konstruksi boiler luar biasa. Pengoperasian dan pemeliharaannya juga sangat mudah, yang telah membantu kami menghemat waktu dan uang untuk pemeliharaan. Saya sangat merekomendasikan ketel uap Fangkuai kepada siapa pun yang membutuhkan solusi pemanasan yang andal."

Jason

Brazil"Kami telah menggunakan boiler minyak termal Fangkuai untuk pabrik kimia kami selama bertahun-tahun dan tidak pernah mengecewakan kami. Ketel ini sangat tahan lama dan tahan terhadap kondisi yang keras. Pengoperasian dan pemeliharaannya juga sangat mudah, yang telah membantu kami menghemat waktu dan uang untuk pemeliharaan. Boiler minyak termal Fangkuai adalah yang terbaik dan saya sangat merekomendasikannya kepada siapa pun yang membutuhkan solusi pemanasan yang andal."

Perubahan

Cina"Layanan pelanggan di Fangkuai adalah yang terbaik. Mereka membantu saya memilih boiler yang sempurna untuk kebutuhan saya dan memberikan dukungan yang luar biasa selama proses berlangsung. Proses pemasangannya juga sangat lancar dan ketelnya melebihi ekspektasi saya. Sangat mudah digunakan dan dirawat, dan efisiensi energinya luar biasa. Saya sangat merekomendasikan produk Fangkuai kepada siapa pun yang membutuhkan solusi pemanasan yang andal dan efisien."

Juan

Meksiko