Caldaie a vapore elettriche efficienti e affidabili

Caldaie a vapore alimentate a biomassa ad alta efficienza

Caldaie a vapore a carbone affidabili ed efficienti

Caldaie a vapore a gasolio affidabili per applicazioni industriali

Caldaie ad acqua calda a carbone di alta qualità

Caldaie ad acqua calda alimentate a biomassa affidabili ed efficienti

Bollitori elettrici per acqua calda efficienti e affidabili

Caldaie ad acqua calda a gas efficienti e affidabili

Generatore di vapore a biomassa - Soluzione energetica efficiente e sostenibile

Generatore di vapore elettrico ad alte prestazioni per uso industriale

Generatore di vapore a gas ad alta efficienza

Generatore di vapore diesel potente ed efficiente per uso industriale

Risparmia energia e riduci i costi con il risparmio energetico della caldaia Fangkuai

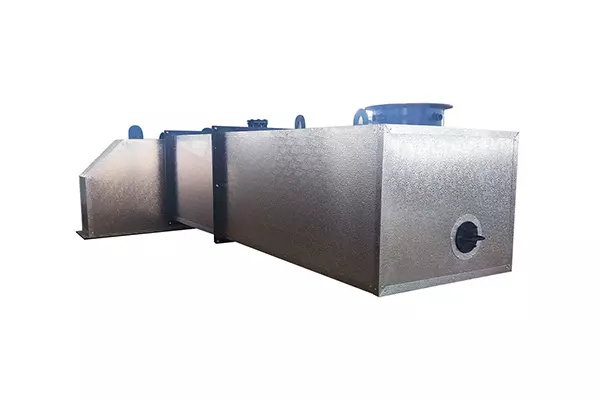

Disaeratore caldaia: La soluzione efficiente per i sistemi a vapore

Bruciatore della caldaia di Fangkuai: La soluzione definitiva per alta efficienza e basse emissioni

Serbatoio acqua calda caldaia | Soluzione affidabile e conveniente per le esigenze di acqua calda

Vendite di caldaie Zhengzhou Fangkuai Co., srl. è una filiale della Fangkuai Boiler Company, mainly responsible for the domestic and foreign trade of Fangkuai Boiler.Fangkuai Headquarters Base has a single-building R&D center, un laboratorio in condizioni di lavoro completo e due di produzione impianti, con una superficie produttiva di 120.000 mq. È l'impresa leader in Cina con capacità di elaborazione dell'automazione delle caldaie, e i suoi prodotti vengono esportati in molti paesi e regioni.

vVisualizza le recensioni dei nostri clienti

"Il servizio clienti di Fangkuai è di prim'ordine. Mi hanno aiutato a scegliere la caldaia perfetta per le mie esigenze e mi hanno fornito un grande supporto durante tutto il processo. Anche il processo di installazione è stato molto fluido e la caldaia ha superato le mie aspettative. È molto facile da usare e mantenere, e l'efficienza energetica è notevole. Consiglio vivamente i prodotti Fangkuai a chiunque necessiti di soluzioni di riscaldamento affidabili ed efficienti."

Giovanni

Messico"La caldaia ad olio diatermico di Fangkuai è molto facile da usare e manutenere. Ci ha aiutato a risparmiare tempo e denaro sulla manutenzione, che ha portato a notevoli risparmi sui costi. La qualità dei materiali e la costruzione della caldaia sono eccezionali. È anche molto efficiente dal punto di vista energetico, che ci ha aiutato a risparmiare sulle nostre bollette energetiche. Consiglio vivamente la caldaia a olio diatermico di Fangkuai ."

Allen

Brasile"Utilizziamo da anni la caldaia ad olio diatermico Fangkuai per il nostro impianto chimico e non ci ha mai deluso. La caldaia è molto resistente e può resistere a condizioni difficili. È anche molto facile da usare e mantenere, che ci ha aiutato a risparmiare tempo e denaro per la manutenzione. Le caldaie ad olio diatermico Fangkuai sono di prim'ordine e le consiglio vivamente a chiunque necessiti di soluzioni di riscaldamento affidabili."

Chang

Cina"Il generatore di vapore di Fangkuai è perfetto per la mia piccola impresa. È molto facile da usare e richiede una manutenzione minima. È anche molto efficiente dal punto di vista energetico, che mi ha aiutato a risparmiare sulle mie bollette energetiche. Anche il servizio clienti di Fangkuai è eccellente. Sono molto reattivi e sempre disposti ad aiutare. Consiglio vivamente i generatori di vapore di Fangkuai."

Ahmad

Egitto"La caldaia per l'acqua calda di Fangkuai è fantastica. Si riscalda in modo rapido ed efficiente, e l'acqua rimane calda per molto tempo. Non abbiamo mai avuto problemi e ha apportato un miglioramento significativo alle nostre operazioni quotidiane. Anche il processo di installazione è stato molto fluido e il servizio clienti è stato eccellente. Consiglio vivamente le caldaie ad acqua calda di Fangkuai."

Sara

Canada"Utilizziamo da anni la caldaia ad olio diatermico Fangkuai per il nostro impianto chimico e non ci ha mai deluso. La caldaia è molto resistente e può resistere a condizioni difficili. È anche molto facile da usare e mantenere, che ci ha aiutato a risparmiare tempo e denaro per la manutenzione. Le caldaie ad olio diatermico Fangkuai sono di prim'ordine e le consiglio vivamente a chiunque necessiti di soluzioni di riscaldamento affidabili."

Chang

Cina"L'attrezzatura ausiliaria di Fangkuai ha reso il mio sistema di caldaie ancora migliore. La qualità dell'attrezzatura è eccezionale ei prezzi sono molto ragionevoli. L'apparecchiatura ha contribuito a migliorare l'efficienza e le prestazioni del mio sistema di caldaie, che ha portato a notevoli risparmi sui costi. Consiglio vivamente l'attrezzatura ausiliaria di Fangkuai a chiunque necessiti di accessori per caldaie di alta qualità."

Maryk

UK"La caldaia ad olio diatermico di Fangkuai è molto facile da usare e manutenere. Ci ha aiutato a risparmiare tempo e denaro sulla manutenzione, che ha portato a notevoli risparmi sui costi. La qualità dei materiali e la costruzione della caldaia sono eccezionali. È anche molto efficiente dal punto di vista energetico, che ci ha aiutato a risparmiare sulle nostre bollette energetiche. Consiglio vivamente la caldaia a olio diatermico di Fangkuai ."

Allen

Brasile"Sono rimasto molto colpito dalla qualità della caldaia per l'acqua calda di Fangkuai. È costruito per durare e ha superato le mie aspettative. Anche il processo di installazione è stato molto fluido e il servizio clienti è stato eccellente. La caldaia per l'acqua calda è molto facile da usare e manutenere, e l'efficienza energetica è notevole. Consiglio vivamente le caldaie ad acqua calda di Fangkuai."

Jack

Australia