Industrial steam boilers range in price from $5,000 to $300,000. Factors that affect price include the cost of the boiler itself, installation fees, and ongoing maintenance costs. Prices for industrial steam boilers vary according to size, fuel type, and efficiency class.

What is an industrial steam boiler?

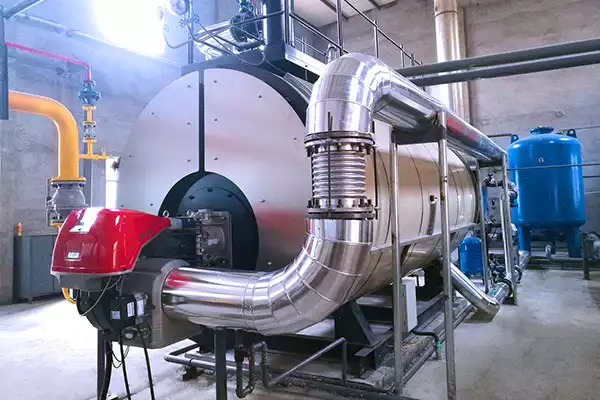

An industrial steam boiler is a large vessel that generates high-pressure steam for various industrial processes. It is designed to heat water and convert it into steam, which can be used for heating, power generation, or other industrial applications.Industrial boilers are commonly used in industries such as manufacturing, power generation, chemical processing, and food processing. They come in different sizes and configurations, depending on the specific needs of the industry.

Get an online fixed price in 20 seconds:

Q What kind of fuel does your boiler use?

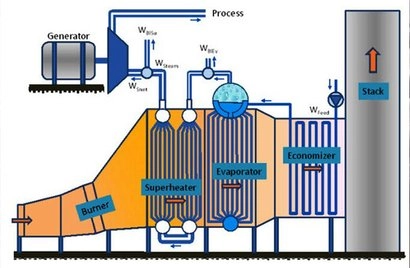

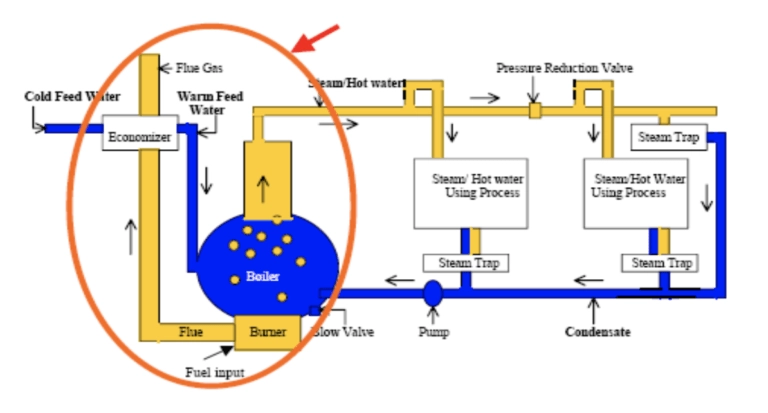

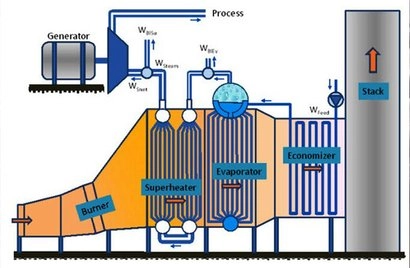

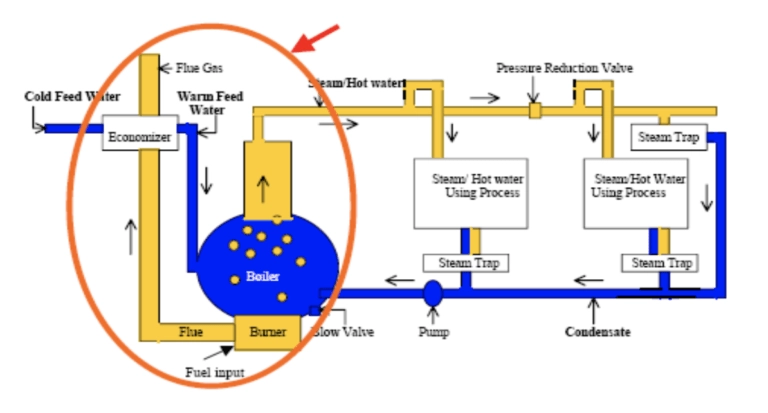

How does an industrial steam boiler work?

An industrial steam boiler operates by igniting a fuel source within a combustion chamber, generating intense heat. This heat is then transferred to water-filled tubes, causing the water to absorb heat and transform into steam. The steam is separated and directed to power various industrial processes. The condensed steam returns as condensate, and safety measures and precise monitoring systems ensure efficient and safe operations across diverse industries.

After the water is converted into steam, it travels through pipes to its designated point of use. It can be utilized for purposes such as heating spaces, powering turbines, or driving industrial processes. Throughout this process, any dissolved solids remain in the boiler water as steam is produced.

Industrial Steam Boiler Composition

The composition of an industrial steam boiler can vary depending on its design and purpose. Generally, an industrial steam boiler consists of several key components:

- Boiler Shell: The shell is the outermost part of the boiler that contains the boiler internals. It provides structural support and protection against heat and pressure.

- Combustion Chamber: Also known as the furnace, the combustion chamber is where the combustion of fuel takes place. It houses the burners and provides a space for the flame and hot gases to interact with the heat exchanger surfaces.

- Heat Exchanger Surfaces: These are the areas where heat is transferred from the hot gases to the water. Heat exchanger surfaces can be in the form of tubes, firetubes or watertubes, or other configurations depending on the boiler type.

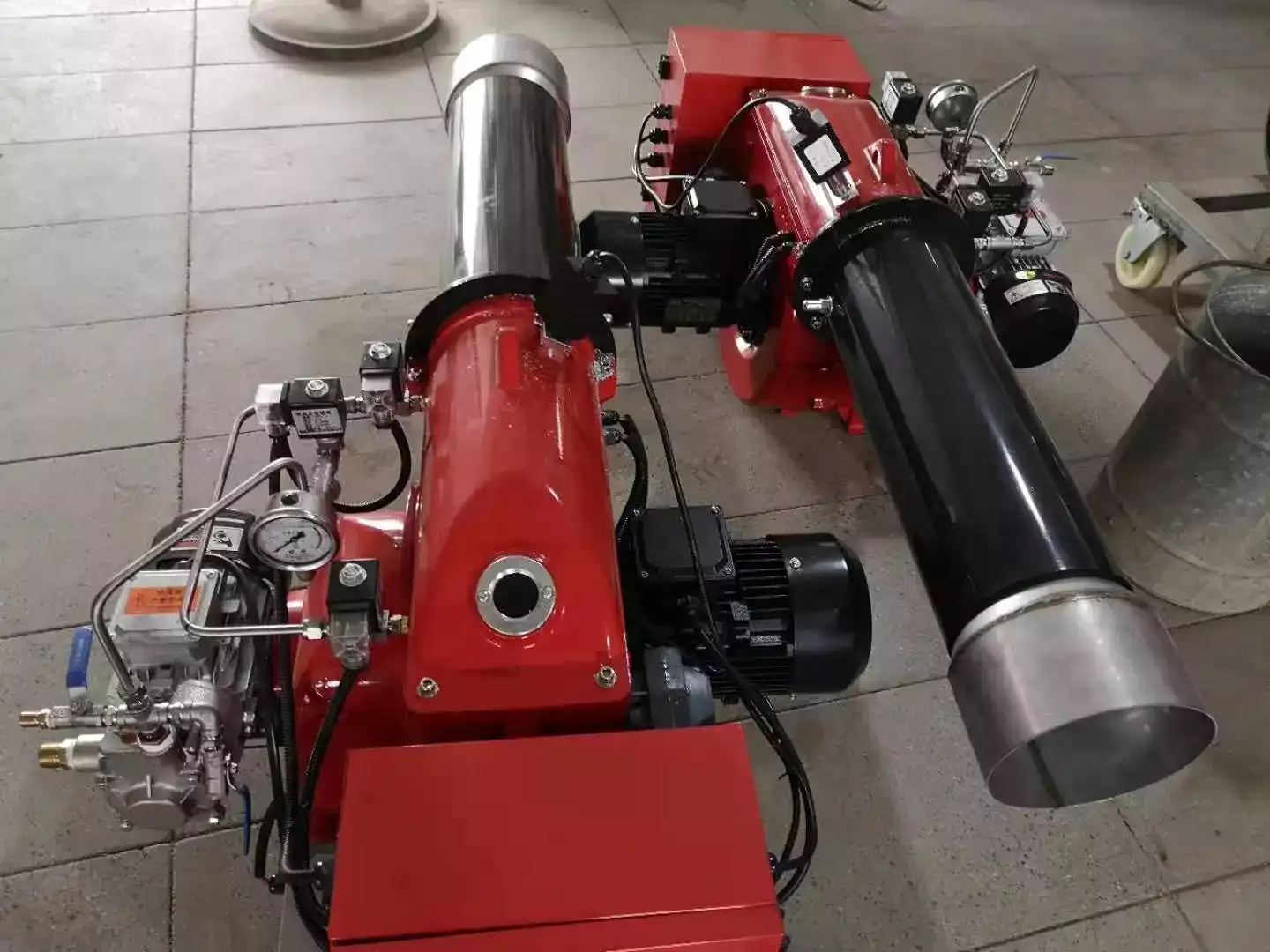

- Burners: The burners are responsible for the combustion of the fuel, ensuring efficient and controlled heat generation. They mix fuel (such as natural gas, oil, or coal) with air and ignite it to create a flame.

- Water Circulation System: Industrial steam boilers have a water circulation system that ensures continuous circulation of water, allowing for the transfer of heat from the heat exchanger surfaces to the water. This system typically includes pumps, pipes, and drums.

- Control Systems: Modern industrial steam boilers often incorporate advanced control systems that monitor and regulate various parameters such as fuel input, water level, pressure, and temperature to optimize boiler performance and safety.

Industrial boiler application industry

Industrial steam boilers have a wide range of applications in various industries. Some of the most common industries that use industrial steam boilers include:

- Power Generation: Industrial steam boilers are used to generate electricity by heating water and producing steam to spin turbines that generate electricity. Power plants utilize large industrial steam boilers to produce reliable and efficient electricity for homes, factories, and other facilities.

- Chemical Industry: The chemical industry uses industrial steam boilers for various processes such as chemical reactions, distillation, and sterilization. These processes require high-temperature steam, precise temperature control, and clean steam to prevent contamination.

- Food and Beverage Industry: Industrial steam boilers are widely utilized in the food industry for processes such as cooking, pasteurization, and sterilization. These applications require precise temperature control and clean steam to ensure food safety and quality.

- Textile Industry: The textile industry utilizes industrial steam boilers for processes such as dyeing, spinning, and weaving. Steam is used to heat water, generate the necessary temperatures needed for these processes, and maintain precise temperature control.

- Healthcare Industry: The healthcare industry relies on industrial steam boilers for sterilization processes, such as in hospitals, laboratories, and medical device manufacturing facilities. Clean steam is critical to ensure patient and product safety.

Other industries that commonly use industrial steam boilers include paper and pulp, oil and gas, and pharmaceuticals. Given the versatility of industrial steam boilers, their uses across industries continue to expand as companies seek to improve efficiency, reduce cost, and meet strict environmental and safety regulations.

How long is the service life of industrial boilers?

The service life of industrial boilers varies based on factors such as design quality, maintenance practices, usage intensity, and the type of fuel used. Typically, well-maintained boilers can last anywhere from 20 to 50 years. Regular inspections, maintenance, and adherence to recommended operational guidelines can significantly extend the operational lifespan of these crucial industrial assets.

What is the difference between a commercial boiler and an industrial boiler?

The main difference between a commercial boiler and an industrial boiler lies in their intended applications and scale of operation.

1. Scale of Operation:

- Commercial boilers: mostly used in small applications such as office buildings, hotels, schools and hospitals. They mainly provide heating and hot water to meet demand.

- Industrial Boilers: Mainly used in larger scale operations such as power plants, factories, refineries and chemical plants. They provide the necessary steam or heat required by industrial processes.

2. Purpose and Applications:

- Commercial Boilers: Primarily used to provide space heating and hot water for small commercial or institutional settings. They are designed for efficient heating and hot water supply to meet the needs of specific facilities.

- Industrial Boilers: Used in a wide range of industrial applications. They typically involve large-scale processes that require high-temperature steam or heat, such as power generation, chemical processing, oil refining, and food processing. Industrial boilers are generally stronger and able to withstand higher pressures and temperatures to meet the specific needs of industrial processes.

3. Design and Features:

- Commercial Boilers: Employing a simple design such as a fire tube boiler, it provides a cost-effective heating solution and requires minimal maintenance compared to more complex water tube boilers. They are designed for efficient and reliable heating in commercial environments.

- Industrial Boilers: Available in a variety of designs, including fire tube, water tube, etc., depending on the application. Industrial boilers are built with durability and efficiency in mind, employing advanced features for precise control, high efficiency and safety.

What are the most common industrial boilers?

There are several types of industrial boilers commonly used across different industries including:

1. Firetube Boilers:

- Fire tube boilers are often used in small industrial applications. These boilers are designed as a cylindrical shell with pipes passing through the center of the shell. Hot gases from the combustion travel through the pipes, heating the water surrounding the pipes to create steam.

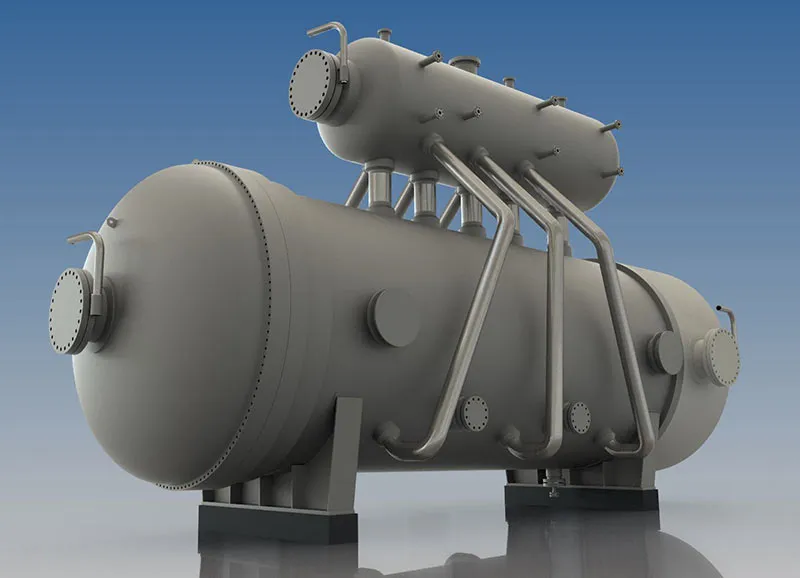

2. Watertube Boilers:

- Watertube boilers are typically used in larger-scale industrial processes and power generation applications. They are designed with a cylindrical drum-shaped shell, with tubes carrying water and steam running through the shell. The hot gases produced from combustion pass over the outside of the tubes, which heats the water inside the tubes. Watertube boilers can be further classified into various designs, such as A-type, O-type, D-type, or flexible tube boilers, depending on the configuration of the mud and steam drums.

3. Electric Boilers:

- Electric boilers produce steam or hot water using electricity instead of combustion. They are popular for their energy efficiency and low environmental impact, making them suitable for specific types of industrial processes.

4. Biomass Boilers:

- Biomass boilers use organic materials, such as wood or agricultural waste, as fuel to produce steam or hot water for industrial processes. They are popular for their low carbon footprint and renewable fuel source, with some models capable of producing clean energy from waste materials.

5. Steam Superheaters:

- Steam superheaters are specialized devices used in conjunction with boilers to produce high-temperature steam, typically for power generation or industrial processes.

How efficient are industrial boilers?

The efficiency of industrial boilers can vary depending on several factors such as the type of fuel used, the design of the boiler, and maintenance practices, among others. According to Energy.gov, the efficiency of an industrial boiler can typically range from 70% to over 90% depending on the type of boiler and operational conditions. However, Energy.gov also notes that properly maintaining and tuning boilers can significantly improve their efficiency and performance.

There are several ways to improve boiler efficiency, such as improving combustion control, installing heat recovery systems, improving insulation, and using high-efficiency burners. Improving the efficiency of industrial boilers can result in significant energy savings and reduce operating and maintenance costs over the life of the boiler.

Industrial electric steam boiler price

The price of an industrial electric steam boiler can vary depending on several factors such as the boiler’s capacity, design, function, and location. The cost of industrial electric steam boilers can range from $1,000 to $15,000 each, going up to $60,000 or more for larger operations requiring more capacity and functionality. However, these prices are general estimates only and should be considered as such.

In addition to the cost of the boiler itself, there are additional costs associated with the installation, maintenance and ongoing operation of the boiler. These costs may vary based on factors such as the availability and cost of electricity, water quality, and local regulatory requirements.

Conclusion

Correct selection of boiler scale and high-efficiency equipment suitable for the demand will be one of the important factors to ensure the smooth operation of industrial production. Choosing the right industrial steam boiler can not only increase the efficiency and sustainability of industrial production, but also reduce energy consumption and environmental impact. For industrial companies, this is an important step towards sustainable development and green production.

If you have any questions or need more information about industrial steam boilers, welcome to contact us on WhatsApp +86 188 3890 8339, we look forward to your message.

Get FREE Local Boiler Quotes today

Get FREE Local Boiler Quotes today

View Reviews of our Customer

"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"I am very impressed with the quality of Fangkuai's hot water boiler. It is built to last and has exceeded my expectations. The installation process was also very smooth and the customer service was excellent. The hot water boiler is very easy to operate and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's hot water boilers."

Jack

Australia"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt