What Are Gas Fired Steam Boilers For Sale?

A gas-fired steam boiler is a type of boiler that uses natural gas or propane as its fuel source. It heats water to create steam, which is then distributed throughout a building for heating or industrial processes. The boiler typically consists of a burner, combustion chamber, heat exchanger, and controls. The burner ignites the gas and air mixture inside the combustion chamber, which then heats the water in the heat exchanger. The steam produced by the boiler is then used for various applications, such as heating buildings or powering industrial processes. Some of the advantages of gas-fired steam boilers include their high efficiency, low emissions, and relatively low operating costs compared to other fuel sources.

Working Principle

Gas-fired steam boilers work by heating a water tank using natural gas or propane as fuel. As the water is heated, it produces steam that is distributed throughout a building through pipes. The steam then circulates through radiators, heating coils, or other heat exchange devices to provide heat. The process repeats as the steam cools and condenses back into the water, which is then reheated to produce more steam. This continuous cycle ensures a steady supply of heat.

Gas Fired Steam Boiler Main Components

- Burner: responsible for igniting the fuel and providing heat to the boiler

- Combustion chamber: where the fuel and air mix and burn to generate heat

- Heat exchanger: transfers the heat generated by the combustion process to the water in the tank

- Water tank: stores the water to be heated and converted into steam

- Safety valve: ensures that the pressure inside the boiler does not exceed a safe limit

- Control system: regulates and monitors the boiler’s operation, including temperature and pressure levels.

Steam Boiler Advantages

- Efficient: Gas-fired steam boilers have high-efficiency ratings and can save energy and money compared to other types of boilers.

- Clean-burning: Natural gas is a clean-burning fuel, which means it produces fewer emissions and pollutants than other fossil fuels.

- Versatile: Gas-fired steam boilers can be used for a variety of purposes, including heating buildings, generating electricity, and powering industrial processes.

- Easy to maintain: Gas-fired steam boilers are relatively easy to maintain and repair, and replacement parts are readily available.

- Safe: Gas-fired steam boilers have safety features to prevent accidents, such as automatic shut-off valves and safety relief valves.

Gas-Fired Steam Boiler Vs Oil-Fired Steam Boilers

Gas-fired steam boilers and oil-fired steam boilers are two types of boilers used for heating and industrial processes. Both have their advantages and disadvantages.

Gas-fired steam boilers are typically more efficient and have lower emissions than oil-fired steam boilers. They also tend to have lower operating costs since natural gas is generally less expensive than oil. However, gas-fired steam boilers can be more expensive to install, and they may not be suitable for areas without access to natural gas.

Oil-fired steam boilers, on the other hand, are more versatile since they can run on a variety of fuel sources, including diesel, kerosene, and heating oil. They are also typically more durable than gas-fired steam boilers and may have longer lifespans. However, oil-fired steam boilers tend to have higher operating costs due to the higher cost of oil, and they may produce more emissions than gas-fired steam boilers.

Ultimately, the choice between a gas-fired steam boiler and an oil-fired steam boiler depends on factors such as cost, fuel availability, and environmental concerns.

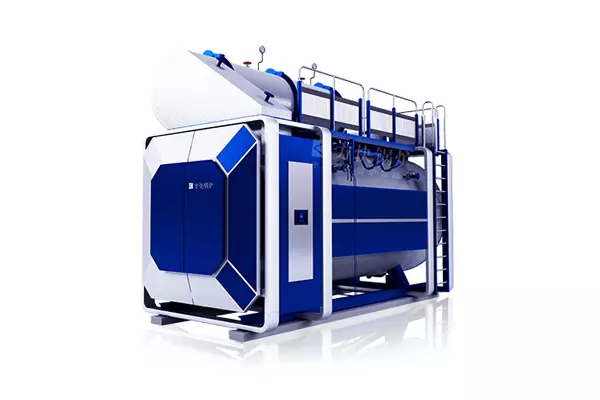

Why Choose Fangkuai Gas Steam Boiler?

When it comes to gas-fired steam boilers, Fangkuai Boiler stands out as a top choice. Fangkuai is a trusted brand that has been providing high-quality boilers for years. One of the main advantages of Fangkuai’s gas-fired steam boilers is their efficiency. They are designed to minimize energy consumption and reduce operating costs. In addition, Fangkuai’s gas-fired steam boilers are built with high-quality materials and components, ensuring long-lasting performance and reliability. Whether you’re looking to heat a large industrial facility or a small commercial space, Fangkuai has the perfect gas-fired steam boiler for your needs. Trust in Fangkuai’s expertise and experience to provide you with a top-performing, efficient, and reliable gas-fired steam boiler.

Gas-Fired Steam Boiler Manufacturers

As a Gas-Fired Steam Boiler manufacturer, Fangkuai Boiler has been providing high-quality and reliable boilers for many years. With a focus on innovation and technology, Fangkuai Boiler has become a leading name in the industry. Their Gas-Fired Steam Boilers are designed to be energy-efficient and easy to use, making them a great choice for both residential and commercial applications.

Fangkuai Boiler’s Gas-Fired Steam Boilers are manufactured with the highest standards of quality and safety in mind. Their boilers are made from high-quality materials and are designed to last for years to come. With their commitment to customer satisfaction and their expertise in the industry, Fangkuai Boiler is a trusted name in Gas-Fired Steam Boilers.

If you’re looking for a reliable and efficient Gas-Fired Steam Boiler, look no further than Fangkuai Boiler. Their expertise and commitment to quality make them a top choice for customers around the world.

Gas-Fired Steam Boiler Goods Delivery

Based on good quality and decades of experience, the equipment which is manufactured by FANGKUAI was exported to different countries. The equipment will be packed and loaded in our factory, and then be shipped to our clients safe and sound.