What Are Biomass Steam Generators?

Biomass steam generators are cutting-edge equipment that utilizes renewable and organic materials to produce steam with minimal environmental impact. They are an efficient and sustainable energy solution that can meet various energy needs across different industries.

How Does A Biomass Steam Generator Work?

Biomass steam generators work by burning organic materials such as wood chips, serragem, and agricultural waste to produce heat. The heat then boils water in the generator, creating steam that can be used to power various equipment. The steam produced by the biomass steam generator is of high quality and can be used in different industrial applications.

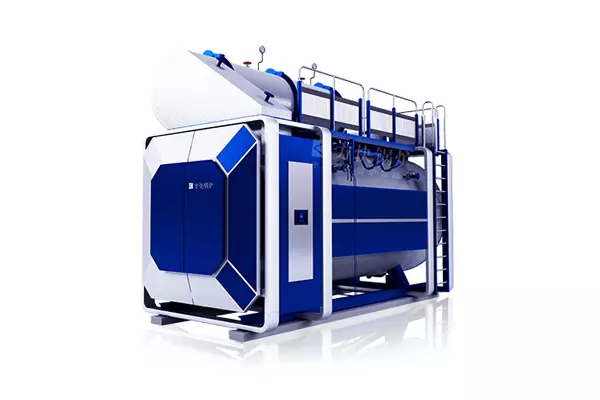

Biomass Steam Generator Main Components

- Combustion chamber

- Trocador de calor

- Fuel feeding system

- Ash removal system

- Painel de controle

Biomass Steam Generator Advantages

- Environmentally friendly and sustainable energy solution

- Lower carbon footprint compared to traditional energy sources

- Higher efficiency and lower operating costs

- Reduced dependency on fossil fuels

- Easy maintenance and long lifespan

Biomass Steam Generator VS Coal Steam Generator

Compared to coal steam generators, biomass steam generators produce lower emissions and have a lower impact on the environment. They also have higher fuel flexibility, allowing them to use various organic materials as fuel. Adicionalmente, biomass steam generators have a higher efficiency and lower operating costs, making them a more economical and sustainable option.

Porque escolher-nos? Fangkuai Boiler is a leading manufacturer of biomass steam generators, committed to providing innovative and sustainable energy solutions to our clients. Our biomass steam generators are made of high-quality materials and are designed for easy installation and maintenance. With our reliable products and exceptional customer service, we ensure that our clients receive the best value for their investments.

Biomass Steam Generator Manufacturers

Na caldeira Fangkuai, we are dedicated to providing our clients with the highest-quality biomass steam generators. Our products are designed and manufactured by a team of experienced professionals, ensuring that our clients receive the best value for their investment.

Biomass Steam Generator Goods Delivery

We provide timely and reliable delivery of our biomass steam generators to our clients. Our products are carefully packaged and delivered with the utmost care to ensure that they arrive in excellent condition.

Baseado em boa qualidade e décadas de experiência, o equipamento fabricado pela FANGKUAI foi exportado para diversos países. O equipamento será embalado e carregado em nossa fábrica, e então ser enviado aos nossos clientes sãos e salvos.