In recent years, with rapid economic growth, environmental pollution has become a pressing concern. Energy-saving and emission reduction efforts are receiving increased attention from relevant authorities. As a clean energy source, natural gas has gradually replaced kerosene as the primary fuel for boilers, finding widespread use in industrial production. However, during boiler operations, the issue of incomplete gas combustion remains a challenge, impacting energy efficiency, environmental protection, and, to a significant extent, the safe operation of boilers.

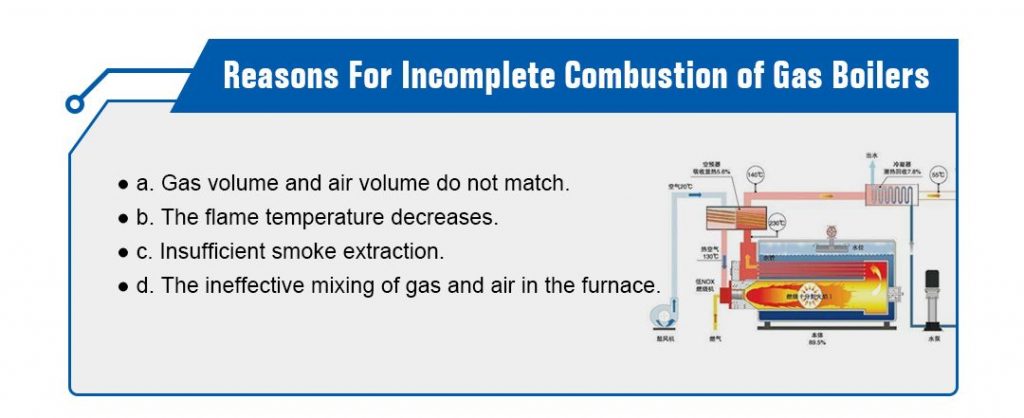

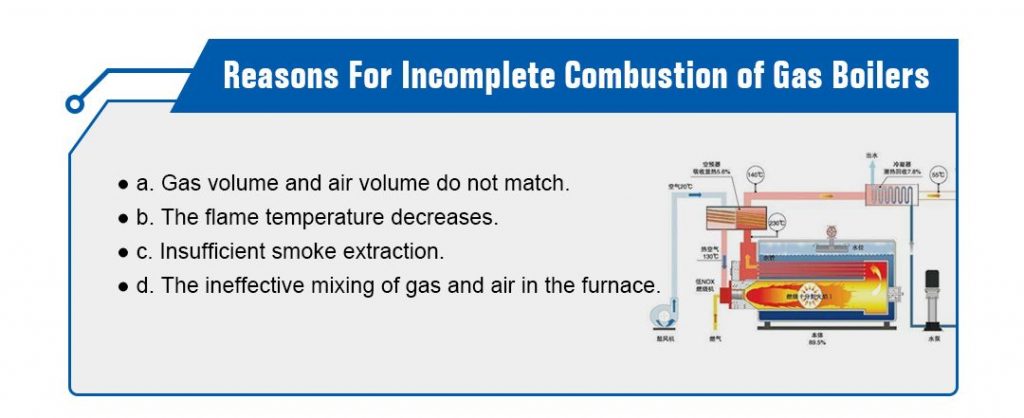

Causes of Incomplete Combustion in Gas-Fired Boilers

Incomplete combustion in gas boilers not only reduces thermal efficiency but also introduces various hazards. The primary causes are as follows:

1. Mismatch Between Gas and Air Volumes:

During boiler operation, the blower pressurizes air and mixes it with gas in the furnace for combustion. If the combustion adjustment is not properly managed, the gas and air volumes may not match, leading to incomplete combustion and reduced operational efficiency.

2. Decrease in Flame Temperature:

To ensure stable combustion and a complete flame, the flame must be maintained at a standard temperature. Incomplete combustion occurs if the flame’s temperature drops due to contact with cold objects.

3. Insufficient Smoke Extraction:

Efficient removal of flue gas is crucial for maintaining combustion efficiency. Poorly controlled flue gas discharge can lead to flue gas retention in the furnace, resulting in insufficient air supply and incomplete combustion.

4. Ineffective Mixing of Gas and Air:

Inadequate mixing of gas and air within the furnace can easily cause incomplete combustion.

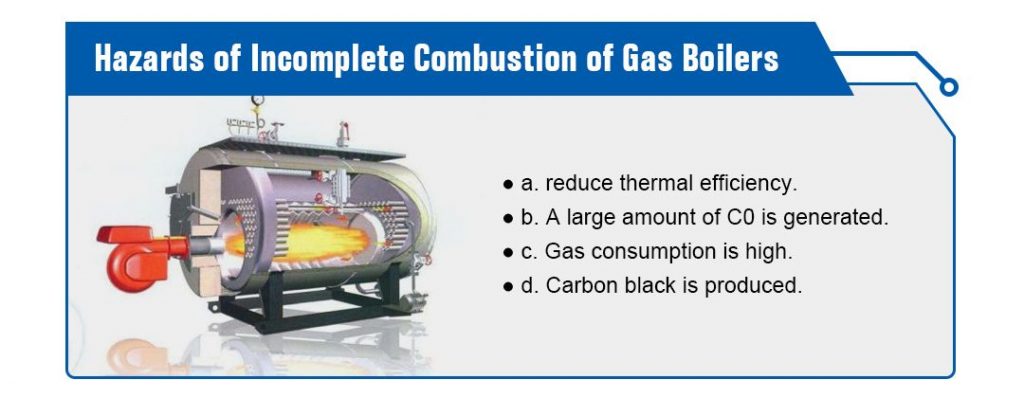

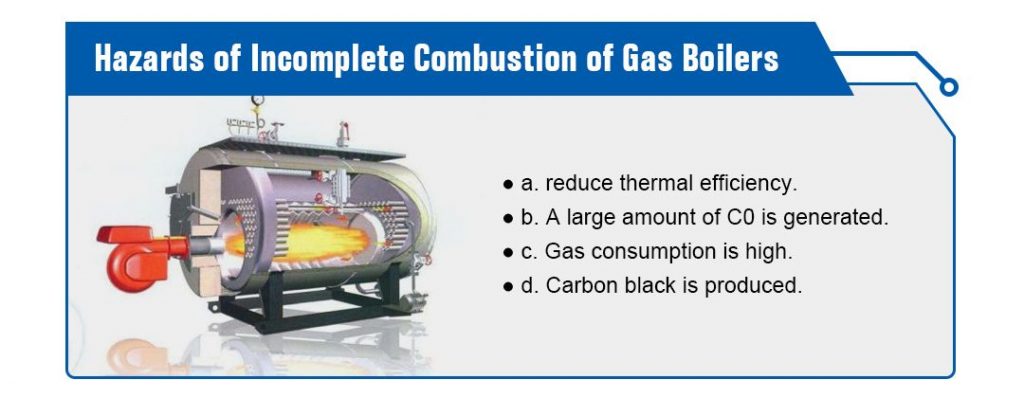

Hazards of Incomplete Combustion in Gas-Fired Boilers

1. Reduced Thermal Efficiency:

Incomplete combustion creates a reducing environment within the boiler furnace, leading to the accumulation of carbon deposits on heat transfer surfaces. This increases thermal resistance, decreases heat transfer rates, raises exhaust gas temperatures, and results in significant heat loss during exhaust, all of which negatively impact boiler efficiency.

2. Generation of CO:

Incomplete combustion produces large amounts of CO, posing significant health risks to operators and increasing the likelihood of boiler explosion accidents.

3. Increased Gas Consumption:

Incomplete combustion means some gas in the furnace does not participate fully in the combustion process, leading to higher gas consumption and reduced boiler economy.

4. Production of Carbon Black:

During gas boiler operation, carbon particles form as a result of incomplete combustion. These particles are not fully burned and are carried away by combustion products, leading to soot formation and environmental pollution.

Technical Improvement Measures for Incomplete Combustion

Given the serious consequences of incomplete combustion in gas-fired boilers, the following improvement measures should be implemented:

1. Enhanced Air Volume Control:

To ensure a stable relationship between air and gas volumes, operators should adjust the blower’s moving blades and regulate air supply according to combustion rate and gas volume. An intelligent adjustment system can help control air supply, with quick response mechanisms ensuring stable oxygen content in the furnace.

2. Improved Induced Air Volume Control:

Maintaining stable negative pressure within the boiler furnace is essential for safe operation. Operators should keep the furnace pressure around -200 Pa, using feedback systems to adjust induced air volume effectively.

3. Optimized Oxygen Control in Flue Gas:

Adding a closed-loop control circuit for flue gas oxygen content helps ensure complete combustion by adjusting the gas-to-air ratio based on real-time monitoring.

4. Increased Boiler Hot Air Temperature:

Raising the temperature of the air entering the furnace aids in rapid combustion and stabilizes furnace temperature. Adjusting the hot air recirculation valve and air distribution ensures optimal combustion and improved furnace temperature.

5. Strengthened Energy Conservation Management:

Enhancing energy-saving management involves regular equipment maintenance, improved energy-saving protocols, and training for managers and operators. Monitoring energy consumption and conducting regular combustion tests ensure the boiler operates efficiently.

Conclusion

The incomplete combustion of gas-fired boilers not only reduces thermal efficiency but also causes severe environmental pollution. It also leads to increased gas consumption and poses significant safety risks due to CO production. By addressing the causes of incomplete combustion and implementing technical improvements, FangKuai boilers can achieve full combustion, improving energy efficiency, environmental protection, safety, and economy in boiler operations.

View Reviews of our Customer

"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt