- گھر

- صنعتیں

- صنعتیں

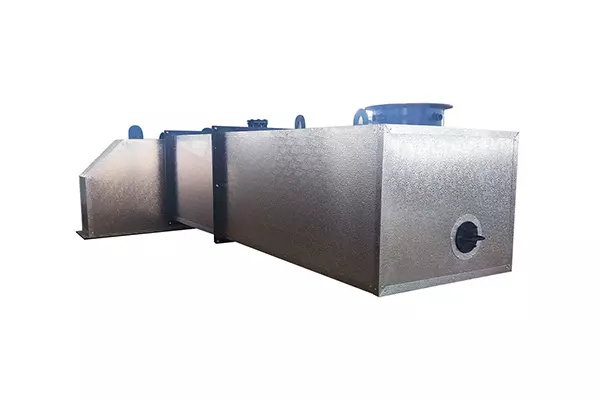

- Fang Kuai بوائلر آن ڈیمانڈ پیش کرتا ہے۔, صنعتی اور تجارتی ایپلی کیشنز کے لیے ماڈیولر بھاپ کے حل جن میں گرمی کے لیے بھاپ کی ضرورت ہوتی ہے۔, نس بندی, نمی, اور مزید.

- مصنوعات

- عالمی معاملہ

- ہمارے بارے میں

- خبریں

- رابطہ کریں۔

ویہمارے گاہک کے جائزے

"Fangkuai میں کسٹمر سروس اعلی درجے کی ہے۔. انہوں نے میری ضروریات کے لیے بہترین بوائلر کا انتخاب کرنے میں میری مدد کی اور پورے عمل میں زبردست مدد فراہم کی۔. تنصیب کا عمل بھی بہت ہموار تھا اور بوائلر میری توقعات سے بڑھ گیا ہے۔. یہ استعمال کرنے اور برقرار رکھنے میں بہت آسان ہے۔, اور توانائی کی کارکردگی قابل ذکر ہے۔. میں Fangkuai کی مصنوعات کی ہر اس شخص کو سفارش کرتا ہوں جسے قابل اعتماد اور موثر حرارتی حل کی ضرورت ہو۔"

جوآن

میکسیکو"Fangkuai کے معاون آلات نے میرے بوائلر سسٹم کو اور بھی بہتر بنا دیا ہے۔. سامان کا معیار غیر معمولی ہے اور قیمتیں بہت مناسب ہیں۔. آلات نے میرے بوائلر سسٹم کی کارکردگی اور کارکردگی کو بہتر بنانے میں مدد کی ہے۔, جس کی وجہ سے لاگت میں نمایاں بچت ہوئی ہے۔. میں Fangkuai کے معاون آلات کی سفارش کرتا ہوں کسی ایسے شخص کو جو اعلیٰ معیار کے بوائلر لوازمات کی ضرورت ہو۔"

میریک

برطانیہ"میں نے اپنی فیکٹری کے لیے فینگکوئی اسٹیم بوائلر خریدا اور یہ مہینوں سے بے عیب کام کر رہا ہے۔. مواد کا معیار اور بوائلر کی تعمیر متاثر کن ہے۔. یہ بہت توانائی کی بچت بھی ہے۔, جس نے ہمیں اپنے توانائی کے بلوں پر رقم بچانے میں مدد کی ہے۔. میں Fangkuai کی مصنوعات کی ہر اس شخص کو سفارش کرتا ہوں جسے قابل اعتماد اور موثر حرارتی حل کی ضرورت ہو۔"

جان

امریکا"میں نے اپنی فیکٹری کے لیے فینگکوئی اسٹیم بوائلر خریدا اور یہ مہینوں سے بے عیب کام کر رہا ہے۔. مواد کا معیار اور بوائلر کی تعمیر متاثر کن ہے۔. یہ بہت توانائی کی بچت بھی ہے۔, جس نے ہمیں اپنے توانائی کے بلوں پر رقم بچانے میں مدد کی ہے۔. میں Fangkuai کی مصنوعات کی ہر اس شخص کو سفارش کرتا ہوں جسے قابل اعتماد اور موثر حرارتی حل کی ضرورت ہو۔"

جان

امریکا"ہم برسوں سے اپنے کیمیکل پلانٹ کے لیے Fangkuai تھرمل آئل بوائلر استعمال کر رہے ہیں اور اس نے ہمیں کبھی مایوس نہیں کیا. بوائلر بہت پائیدار ہے اور سخت حالات کا مقابلہ کر سکتا ہے۔. یہ چلانے اور برقرار رکھنے میں بھی بہت آسان ہے۔, جس نے ہمیں دیکھ بھال پر وقت اور پیسہ بچانے میں مدد کی ہے۔. Fangkuai کے تھرمل آئل بوائلر اعلیٰ درجے کے ہیں اور میں ان کی سفارش ہر اس شخص کو کرتا ہوں جنہیں گرم کرنے کے قابل اعتماد حل کی ضرورت ہو۔"

چانگ

چین"Fangkuai کے بھاپ جنریٹر بہترین ہیں۔. وہ استعمال کرنے میں بہت آسان ہیں اور کم سے کم دیکھ بھال کی ضرورت ہوتی ہے۔. Fangkuai میں کسٹمر سروس بھی غیر معمولی ہے۔. وہ بہت ذمہ دار ہیں اور ہمیشہ مدد کرنے کو تیار ہیں۔. بھاپ جنریٹرز کی توانائی کی کارکردگی بھی قابل ذکر ہے۔, جس نے مجھے اپنے توانائی کے بلوں پر پیسے بچانے میں مدد کی ہے۔. میں Fangkuai کے بھاپ جنریٹرز کی انتہائی سفارش کرتا ہوں۔"

ماریہ

سپین"میں Fangkuai کے گرم پانی کے بوائلر کے معیار سے بہت متاثر ہوں۔. یہ قائم رہنے کے لیے بنایا گیا ہے اور میری توقعات سے بڑھ گیا ہے۔. تنصیب کا عمل بھی بہت ہموار تھا اور کسٹمر سروس بہترین تھی۔. گرم پانی کا بوائلر چلانے اور برقرار رکھنے میں بہت آسان ہے۔, اور توانائی کی کارکردگی قابل ذکر ہے۔. میں Fangkuai کے گرم پانی کے بوائلرز کی بہت زیادہ سفارش کرتا ہوں۔"

جیک

آسٹریلیا"Fangkuai سے بھاپ جنریٹر میرے چھوٹے کاروبار کے لیے بہترین ہے۔. یہ استعمال کرنا بہت آسان ہے اور کم سے کم دیکھ بھال کی ضرورت ہوتی ہے۔. یہ بہت توانائی کی بچت بھی ہے۔, جس نے مجھے اپنے توانائی کے بلوں پر پیسے بچانے میں مدد کی ہے۔. Fangkuai میں کسٹمر سروس بھی بہترین ہے۔. وہ بہت ذمہ دار ہیں اور ہمیشہ مدد کرنے کو تیار ہیں۔. میں Fangkuai کے بھاپ جنریٹرز کی انتہائی سفارش کرتا ہوں۔"

احمد

مصر"Fangkuai سے تھرمل آئل بوائلر چلانے اور برقرار رکھنے میں بہت آسان ہے۔. اس نے دیکھ بھال پر وقت اور پیسہ بچانے میں ہماری مدد کی ہے۔, جس کی وجہ سے لاگت میں نمایاں بچت ہوئی ہے۔. مواد کا معیار اور بوائلر کی تعمیر غیر معمولی ہے۔. یہ بہت توانائی کی بچت بھی ہے۔, جس نے ہمیں اپنے توانائی کے بلوں پر رقم بچانے میں مدد کی ہے۔. میں Fangkuai کے تھرمل آئل بوائلر کی بہت زیادہ سفارش کرتا ہوں۔ ."

ایلن

برازیل