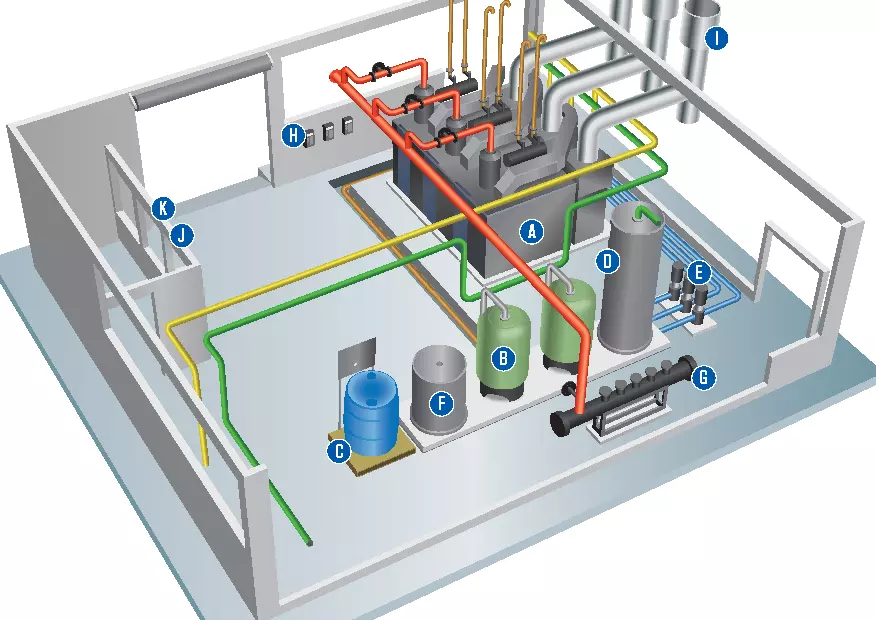

How does a wood boiler system work?

A wood boiler system, also referred to as a wood-fueled heating system, operates by burning wood fuel in a contained environment to generate hot water or steam. The produced hot water or steam is circulated throughout the building to distribute heat.

The process commences with the placement of wood fuel into a firebox, igniting it. Within the boiler, a heat exchanger facilitates the transfer of heat from the burning wood to the water. This heated water is then pushed through pipes to radiators or heat-emitting panels positioned in rooms, or in some instances, to a forced-air system. The cooled water returns to the boiler for reheating, establishing a cyclical process.

Heating with a wood boiler can be more controlled than using wood stoves and furnaces. And since it uses wood as fuel, it tends to have a smaller carbon footprint compared to systems using coal, 气体, 和油.

Types of Wood Boilers

outdoor wood boiler

一个 outdoor wood boiler, also known as an outdoor wood furnace or hydronic heater, is a heating system that utilizes wood as fuel to provide heat for your home, domestic hot water, and other outbuildings. These boilers are located outside the living space and connected to the existing heating distribution system in your home. They are generally more efficient and environmentally friendly than traditional indoor wood stoves.

How it Works

- Burning wood: Wood is burned inside the firebox of the outdoor boiler to create heat. The burn is often more efficient, with less smoke and particulate matter than indoor wood stoves, because outdoor boilers use an air supply system with a forced draft or an underfed combustion system.

- Transferring heat: The heat produced by the burning wood is transferred to a water jacket that surrounds the firebox. This heated water is then circulated via insulated underground pipes to the heat exchangers inside the house or other buildings.

- Distribution: The heat exchangers transfer the heat from the circulating water to the existing heating distribution system in the building. This could be a forced-air system, baseboard radiators, radiant floor heating, or other methods.

- Emission control: Outdoor wood boilers are designed to produce lower emissions and be more environmentally friendly than traditional indoor wood stoves. Some models are equipped with advanced features like gasification technology, which burns both the wood and the gases it produces, resulting in higher efficiency and lower emissions.

优点

- 效率: Outdoor wood boilers are generally more efficient than indoor wood stoves, as they burn wood at a higher temperature, reducing particulate emissions and improving the overall combustion process.

- 安全: By placing the wood boiler outside the living space, the risks of fire, smoke, and carbon monoxide poisoning are reduced.

- Space Saving: An outdoor wood boiler frees up space inside your home that would otherwise be occupied by an indoor wood stove or furnace.

- Multiple Applications: Besides providing heat for your home, outdoor wood boilers can also be used to heat domestic hot water, swimming pools, hot tubs, and other outbuildings.

缺点

- Initial costs: The upfront costs for purchasing and installing an outdoor wood boiler can be higher than those of traditional indoor wood stoves or furnaces.

- 维护: Outdoor wood boilers require regular maintenance, such as cleaning and removing ash, to avoid issues or reduced efficiency.

- Wood supply: Sufficient access to wood fuel is necessary for the long-term use of an outdoor wood boiler.

Indoor Wood Boiler

An indoor wood boiler, or furnace, is a heating system designed to burn wood fuel and use the generated heat to warm a building. They are noted for efficiency, 可靠性, and the ability to adapt to varying types of heating systems.

How it Works

Indoor wood boilers operate slightly differently from their outdoor counterparts due to the nature of indoor use. Here’s a basic outline of their operation:

- Burning the Wood: Wood fuel is burned in an indoor boiler to generate heat, often in a highly efficient, controlled manner. Some indoor wood boilers use advanced systems such as gasification to increase their fuel efficiency.

- Transferring the Heat: The heat derived from the burned wood is then used to heat water contained in a jacket surrounding the firebox. This heated water is used for multiple applications, including indoor heating and providing hot water.

- Heat Distribution: Connected to the building’s heating and plumbing systems, the indoor wood boiler can distribute heat and hot water throughout the building.

优点

- 效率: Some indoor wood boilers, such as the Wood Gun line, are particularly efficient, maximizing energy usage and turning a significant amount of the potential heat energy in the wood into actual heat.

- Quality Control: Premium indoor wood boilers frequently incorporate features such as variable-speed induced draft fans, aiding in faster lighting and designed to prevent smoke leaks.

- Ease of Use: 室内燃木锅炉, such as the Econoburn series, prioritize ease of use and offer high reliability in their design.

缺点

- Safety Concerns: Unlike outdoor boilers, indoor boilers involve the risk of fire hazards and potential indoor air quality issues if not managed and maintained properly.

- 空间要求: Indoor boilers do take up space inside the home, which may not be available for all users.

How efficient are wood boilers?

Wood boilers are generally efficient, but their efficiency depends on various factors such as the type of wood used, the quality of the boiler, the size of the load, and the weather conditions.

通常, wood boilers can achieve an efficiency of around 80% 到 90% when burning high-quality hardwoods. 然而, the use of softwoods or low-quality woods may lead to a decrease in efficiency.

The efficiency of a wood boiler can also vary based on the wood’s moisture content and the operational temperature. Insufficiently dried wood or burning it at a temperature below the optimum range may lead to reduced efficiency.

To maintain efficiency and ensure the longest possible lifespan for your wood boiler, it is important to use high-quality wood and to regularly clean and maintain the boiler. You can also consider using an automatic feeding system to ensure a constant supply of wood and reduce the need for manual feeding, which can further improve efficiency.

Wood vs. 燃气锅炉

燃气锅炉 have higher energy efficiency and lower maintenance costs than wood-burning boilers.

- 能源效率: The thermal efficiency of gas boilers can usually reach more than 90%, while the thermal efficiency of wood-burning boilers is only 80~90% under ideal conditions.

- 燃料来源: The fuel source of gas boilers is mainly natural gas, while the fuel source of wood-burning boilers is wood.

- 维护费用: Gas boilers generally have lower maintenance costs than wood-burning boilers.

- 对环境造成的影响: Using natural gas as fuel reduces environmental impact because natural gas is a clean energy source. Burning wood will produce pollutants such as smoke, exhaust gas, and ash, which will have a certain impact on the environment.

Wood vs. 电锅炉

电锅炉 are safer and smarter than wood-burning boilers.

- 安全可靠: Electric boilers do not produce open flames or high temperatures and are safer and more reliable than coal-fired boilers.

- Clean energy: The electric energy used by electric boilers is a clean energy that does not produce waste gas, waste residue, and other pollutants.

- Intelligent control: The electric boiler comes equipped with an intelligent control system that can automatically adjust temperature and pressure, ensuring easy operation.

- High energy costs: Electric boilers have relatively high energy costs and require a large amount of electricity to maintain operation.

- Requires regular maintenance: Electric boilers require regular maintenance and repairs to ensure their normal operation.

How much does it cost to install a wood boiler?

The cost of installing a wood boiler can vary based on multiple factors, such as the boiler’s size, 类型, 附加功能, 和安装注意事项. According to HomeAdvisor, for an outdoor wood boiler, prices range between $8,000 和 $14,000. Larger systems might average around $12,000.

For higher-end models like large 300,000 BTU gasification boilers, the cost could go up to $20,000. Fixr provides similar data, stating that the national average for installing an outdoor boiler falls between $8,000 和 $20,000. Most individuals, however, tend to spend approximately $12,000 for a 150,000 BTU gasification boiler with heat exchange and pipes designed to heat a 2,500 平方. ft. area in a zone 3 到 5 气候.

结论

Wood boilers are an excellent choice for environmentally conscious homeowners seeking cost-effective heating solutions. Their efficiency, 环境效益, and cost savings make them a compelling option for a greener future.

常见问题解答

What is the average lifespan of a wood boiler?

通常, a well-maintained wood boiler lasts around 20 年. Regular servicing and proper care significantly contribute to its longevity.

Are wood boilers cost-effective in the long run?

绝对地. Though the initial investment might be higher, the operational costs are lower, providing substantial long-term savings.

Can I use any type of wood in a wood boiler?

Using properly seasoned hardwood is advisable for optimal performance. Softwoods can be used but might require more frequent cleaning due to higher resin content.

How often should I clean my wood boiler?

Regular cleaning is recommended, especially during the heating season. 然而, a thorough clean annually before the start of winter is ideal.

Are wood boilers environmentally friendly?

是的, wood boilers are considered environmentally friendly. They use a renewable energy source and have considerably lower emissions compared to fossil fuel-based systems.

What size wood boiler do I need for my home?

The size of the wood boiler depends on the square footage of the area you wish to heat. Consulting with a professional can assist in determining the right size for your needs.