余热锅炉将余热转化为有价值的蒸汽,在工业环境中发挥着至关重要的作用. 这种余热锅炉蒸汽可应用于各种工业应用, 提供显着的节能效果并促进可持续实践. 是否用于发电, 加热, 或冷却系统, 余热锅炉产生的蒸汽帮助工业减少燃料消耗, 降低运营成本, 并提高整体效率.

在本文中, 我们将探讨其好处, 关键应用, 余热锅炉产生蒸汽的节能潜力, 以及最大限度地利用其最佳实践.

什么是余热锅炉及其工作原理?

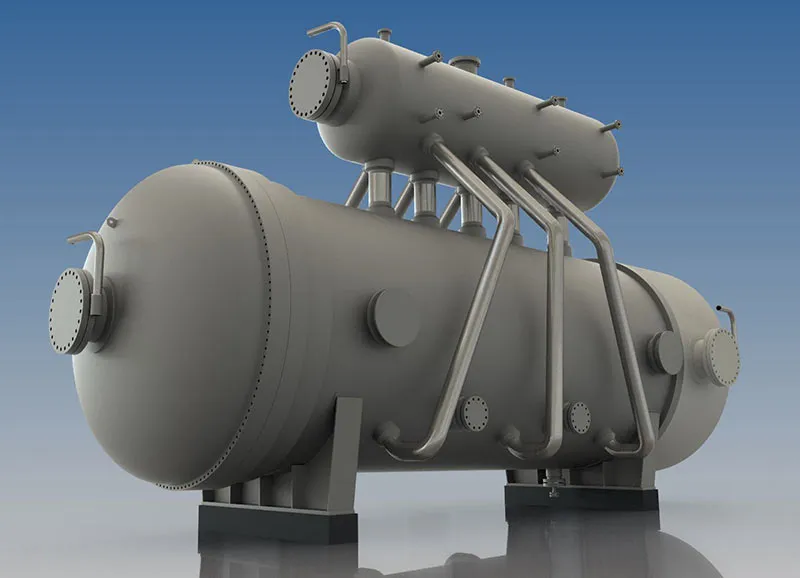

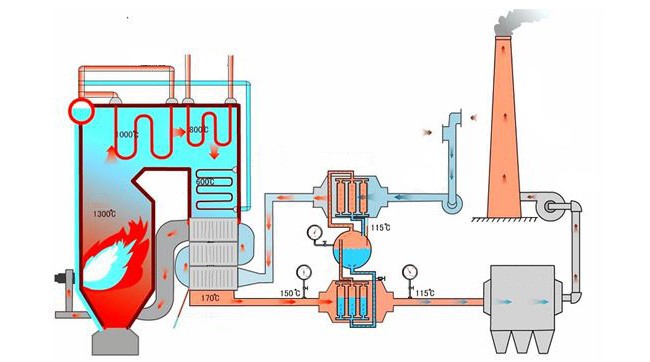

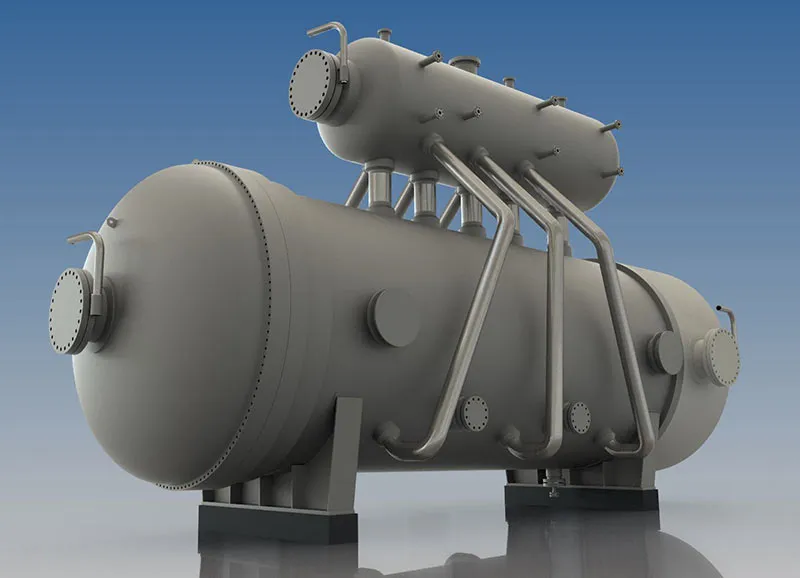

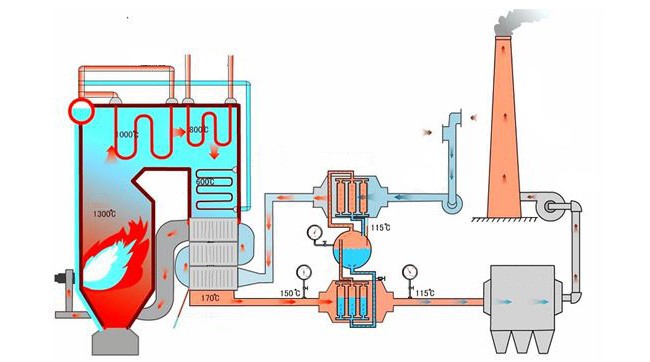

余热锅炉 (WHB) 旨在回收工业过程中的热量, 通常来自熔炉等设备排放的废气, 涡轮机, 或引擎. 而不是让这些热量逸散到环境中, WHB 捕获它并用它来产生蒸汽, 将废热转化为可用能源.

以下是废热锅炉工作原理的简化分解:

- 热源: 工业过程产生的废气通常被释放到大气中. 这些气体携带大量的热能.

- 传播热量: 在 WHB 中, 该热能被传递给水或其他传热流体.

- 蒸汽发生: 当水吸收热量时, 它转化为蒸汽, 可用于各种应用.

通过捕获废热并将其转化为蒸汽, 余热锅炉帮助行业提高能源效率并减少排放, 支持更环保的运营.

余热锅炉产生蒸汽的主要好处

利用废热锅炉产生的蒸汽具有多种优势, 帮助行业提高整体运营效率. 一些主要好处包括:

- 能源效率: WHB 通过利用废热产生蒸汽来最大限度地回收能量. 这减少了对额外燃料来源的需求.

- 节约成本: 利用余热, 工业可以减少燃料消耗, 从而降低能源费用和运营成本.

- 对环境造成的影响: 回收废热可以减少燃烧燃料产生蒸汽的需要,从而有助于减少温室气体排放, 促进更清洁的工业流程.

- 提高生产力: 具有高效的蒸汽供应, 需要热量的过程可以连续运行,无需中断燃料补充.

- 可持续发展: 减少能源浪费和利用可再生蒸汽源支持企业社会责任 (企业社会责任) 倡议并帮助满足排放法规.

余热锅炉蒸汽的主要工业应用

余热锅炉产生的蒸汽用途广泛,可用于多种工业应用. 一些最常见的用途包括:

- 发电: 废热锅炉产生的蒸汽可以驱动涡轮机发电, 要么用于工厂本身,要么用于输出到电网.

- 过程加热: 许多制造过程在不同阶段都需要热量. 余热锅炉蒸汽常用于干燥, 养护, 或在化学加工中.

- 空间供暖: 在较冷的气候下, 蒸汽用于加热工作空间, 办公楼, 或整个工业园区.

- 冷却和制冷系统: 废热蒸汽可用于吸收式制冷机,为冷却系统生产冷冻水, 进一步提高能源效率.

- 海水淡化和水处理: 在缺水地区, 海水淡化过程中使用废热蒸汽将海水转化为淡水.

- 石化行业: 废热锅炉产生的蒸汽对于炼油工艺和石化行业内的化学反应至关重要.

利用余热锅炉蒸汽提高能源效率并降低成本

余热锅炉蒸汽的节能特性是各行业投资这些系统的关键原因之一. 传统锅炉系统需要额外的燃料来产生蒸汽, 这可能会导致能源成本增加. 相比之下, 废热锅炉利用余热产生蒸汽, 有效回收原本会损失的能源.

以下是余热锅炉蒸汽提高能源效率、降低成本的关键方法:

- 降低燃油费用: 依靠废热, 各行业减少对购买燃料的依赖, 立即节省开支.

- 降低维护成本: 利用废热减少主锅炉的磨损, 降低维护频率和成本.

- 最大限度地减少停机时间: 高效的蒸汽回收确保连续的工艺运行, 减少停机时间并提高整体生产力.

利用余热锅炉蒸汽推动可持续发展

随着可持续发展成为现代工业的焦点, 余热锅炉蒸汽在减少环境影响方面发挥着至关重要的作用:

- 减少碳足迹: 通过回收和利用废热, 各行业减少化石燃料消耗, 减少温室气体排放和碳足迹.

- 高效的资源利用: 废热锅炉将废热转化为有用的产品, 确保资源得到充分利用.

- 符合监管标准: 随着能源使用和排放法规变得更加严格, 余热回收可帮助企业满足这些要求并避免罚款或处罚.

- 增强公众认知: 可持续经营不仅有利于环境,还可以改善公众和投资者的看法, 特别是随着越来越多的消费者要求对环境负责的商业行为.

余热锅炉蒸汽的创新工业用途

各行业越来越多地探索利用废热锅炉蒸汽的创新方法,以提高能源效率和可持续性:

- 区域供暖: 一些城市利用余热锅炉蒸汽提供区域供热, 从中央工业工厂向家庭和企业输送热量.

- 混合动力系统: 余热锅炉可以与太阳能等可再生能源集成, 风, 或地热能来创建混合系统,提供更可持续的能源解决方案.

- 热电联产: 余热锅炉产生的蒸汽通常用于热电联产 (热电联产) 系统, 为工厂或周边地区提供电力和热力.

- 先进的海水淡化技术: 废热锅炉蒸汽越来越多地用于创新的海水淡化工艺, 减少将海水转化为饮用水的能源需求.

高效的最佳实践 余热锅炉 操作与维护

最大限度地提高余热锅炉的性能和使用寿命, 行业应遵循这些操作和维护最佳实践:

- 定期检查: 定期检查锅炉的换热面, 蒸汽输出, 和控制系统,以防止效率损失和安全隐患.

- 正确清洁: 保持传热表面无烟灰和碎屑,以确保高效的热交换和最佳的蒸汽产量.

- 监测烟气: 连续测量烟气成分以调整空燃比并确保完全燃烧以最大程度地回收能量.

- 锅炉调试: 定期调整锅炉系统可确保所有组件以最高效率运行并防止不必要的燃料消耗.

结论

余热锅炉蒸汽是工业界提高能源效率的有力工具, 降低运营成本, 并降低对环境的影响. 通过回收原本会被浪费的热量, 行业可以创造更加可持续和高效的运营. 随着能源法规的收紧和可持续发展目标变得更加突出, 余热锅炉的作用将继续增长, 帮助行业向绿色转型, 更节能的解决方案.

V查看我们客户的评论

"我们化工厂一直在使用方快导热油锅炉多年,从未让我们失望过. 锅炉非常耐用,可以承受恶劣的条件. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 方快的导热油锅炉是一流的,我强烈推荐给任何需要可靠供暖解决方案的人。"

张

中国"方快的蒸汽锅炉非常适合我的食品加工业务. 它满足我们的所有要求并且非常可靠. 材料的质量和锅炉的构造非常出色. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 我向任何需要可靠供暖解决方案的人强烈推荐方快的蒸汽锅炉。"

杰森

巴西"方快的蒸汽发生器非常适合我的小生意. 它非常易于使用,需要最少的维护. 它也非常节能, 这帮助我节省了能源费用. 方快的客服也很好. 他们反应灵敏,乐于助人. 强烈推荐方快的蒸汽发生器。"

艾哈迈德

埃及"我们化工厂一直在使用方快导热油锅炉多年,从未让我们失望过. 锅炉非常耐用,可以承受恶劣的条件. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 方快的导热油锅炉是一流的,我强烈推荐给任何需要可靠供暖解决方案的人。"

张

中国"方快的蒸汽锅炉非常适合我的食品加工业务. 它满足我们的所有要求并且非常可靠. 材料的质量和锅炉的构造非常出色. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 我向任何需要可靠供暖解决方案的人强烈推荐方快的蒸汽锅炉。"

杰森

巴西"我为我的工厂购买了一台方快蒸汽锅炉,它已经完美运行了几个月了. 材料的质量和锅炉的结构令人印象深刻. 它也非常节能, 这帮助我们节省了能源费用. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

约翰

美国"我为我的工厂购买了一台方快蒸汽锅炉,它已经完美运行了几个月了. 材料的质量和锅炉的结构令人印象深刻. 它也非常节能, 这帮助我们节省了能源费用. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

约翰

美国"方快的热水锅炉质量让我印象深刻. 它经久耐用,超出了我的预期. 安装过程也很顺利,客服态度也很好. 热水锅炉操作维护非常方便, 能源效率显着. 强烈推荐方快的热水器。"

杰克

澳大利亚"方快导热油锅炉操作维护非常方便. 它帮助我们节省了维护时间和金钱, 这导致显着的成本节约. 材料的质量和锅炉的构造非常出色. 它也非常节能, 这帮助我们节省了能源费用. 强烈推荐方快的导热油锅炉 ."

艾伦

巴西